Slurry Pump volute liner C2110,Slurry pump volute liner G12110,Slurry pump volute liner E4110,Volute liners for slurry pumps, AHZJ type slurry pumps,Naipu slurry pump volute liners, Naipu slurry pumps.Slurry pump volute liners G12110,SLURRY PUMP VOLUTE LINERS G10110

Slurry pumps are suitable for transfering slurries with erosion and high density in all industries sector.

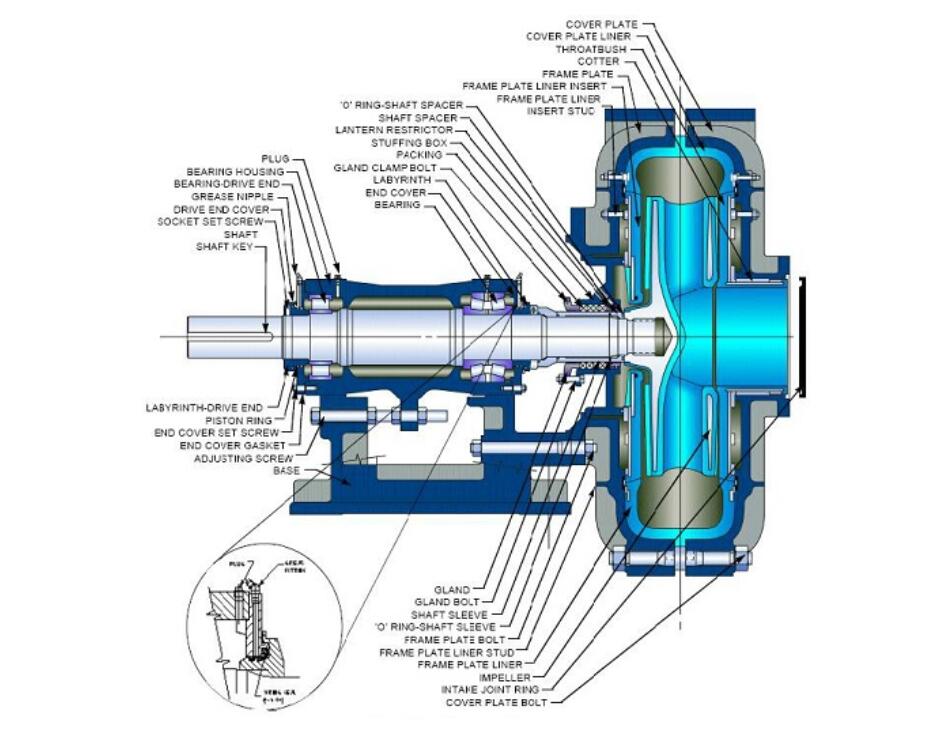

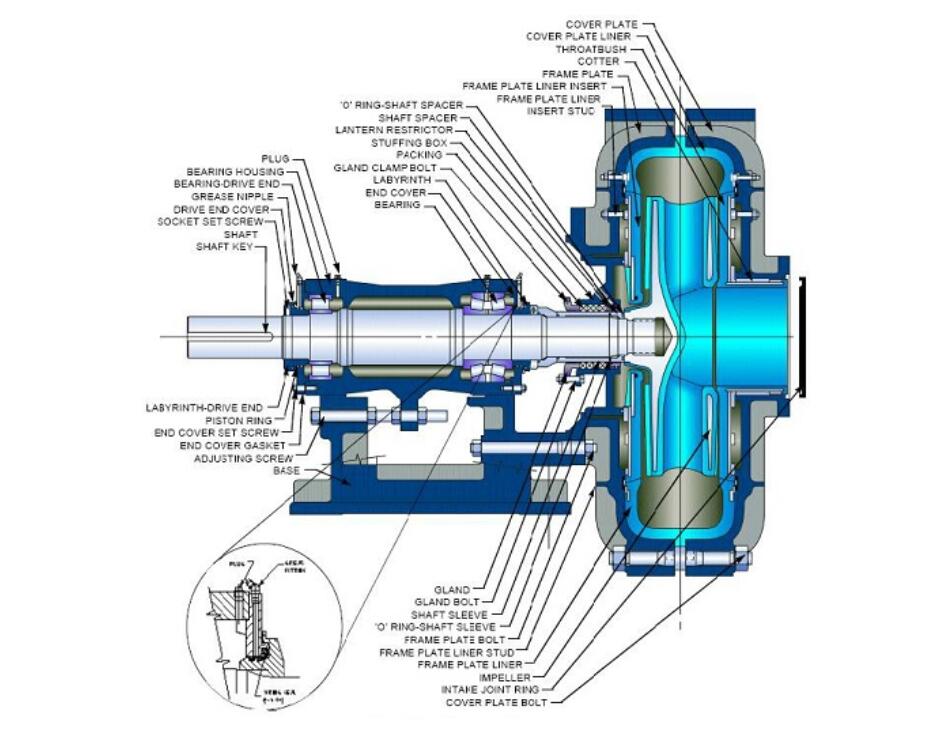

2.Structure of rubber liner horizontal slurry pump

Replacement of slurry pump volute, slurry pump volute liners

| Part No. of Volute | Replacement Slurry Pump Model | Pump Type |

B1110NA | 1.5/1B-AHZJ | AH Horizontal Slurry Pump |

B15110NA | 2/1.5B-AHZJ |

C2110NA | 3/2C-AHZJ |

D3110 | 4/3C-AHZJ, 4/3D-AHZJ |

E4110 | 6/4D-AHZJ, 6/4E-AHZJ |

F6110 | 8/6E-AHZJ, 8/6F-AH, 8/6R-AHZJ |

G8110 | 10/8ST-AHZJ |

G10110 | 12/10ST-AHZJ |

G12110 | 14/12F-AH14/12ST-AHZJ |

H14110 | 16/14TU-AHZJ |

AL2110 | 20A-L | L Horizontal Slurry Pump |

BL5110 | 50B-L |

CL75110NA | 75C-L |

DL10110 | 100D-L |

EL15110 | 150E-L |

SL30110 | 300S-L |

F8110 | 10/8E-M, 10/8F-M, 10/8R-M | M Horizontal Slurry Pump |

F10010 | 12/10F-M, 12/10R-M |

CH1110NA | 1.5/1C-HH | HH High Head Slurry Pump |

DH2110 | 3/2D-HH |

EH3110 | 4/3E-HH |

FH4110 | 6/4F-HH |

FH6110 | 6S-H, 8/6S-H |

DG4131 | 6/4D-G, 6/4E-G | G Gravel Sand Pump |

EG6131 | 8/6E-G |

FG8131 | 10/8F-G, 10/8S-G |

FG10131 | 12/10G-G |

GG12131 | 14/12G-G |

FGH8131 | 10/8F-GH |

GGH10131 | 12/10G-GH |

TG14131 | 16/14TU-GH |

SP4092 | 40PV-SP | SP Vertical Slurry Pump |

SP65092 | 65QV-SP |

SP10092 | 100RV-SP |

SP15092 | 150SV-SP |

SP20092 | 200SV-SP |

SP25092 | 250TV-SP |

SP30092 | 300TV-SP |

SP30092 | 300TV-SP |

3. Besides whole set slurry pumps,we also accept OEM Slurry Pump Parts, such as Impeller, frame plate liner ,throat bushing,etc.

4. If you have any demand of OEM Slurry Pump or OEM Slurry Pump Parts shaft sleeve, impellers,etc,welcome to contact with Shijiazhuang Naipu Pump Co.,ltd.

Slurry pump pump body with replaceable rubber lining, impeller, shield, front and rear sheath are made of wear-resistant decay-resistant rubber.

Adhesive pump is suitable for conveying small particle size, no sharp corners and high concentration of slurry particles, can also transport corrosive slurry.

Seal : packing seal, vice impeller seal, fill the auxiliary impeller seal, mechanical seals and other types.

A brief introduction of the slurry pumps we offer:

Slurry Pump Series:

1. Metal Lined Slurry Pump, SH Type; 2. Rubber Lined Slurry Pump (SHR Type); 3. Hi-Pressure Slurry Pump (SBH Type);

Gravel Pump Series:

1. Hard Metal Sand Pump (SG, SHG Type); 2. WN Dredging Pump (WN Type);

Sump Pump Series:

1. Metal Vertical Slurry Pump (SV Type); 2. Rubber Vertical Slurry Pump (SVR Type);

Local Pump Series:

1. Power Plant Slurry Pump (ZBG Type); 2. Coal Washing Slurry Pump (ZJ Type);

Froth Pump Series

Slurry Pump Parts :

1. Metal Pump Parts; 2. Rubber Pump Parts; 3. OEM Pump Parts

Use:

Slurry Pumps are suitable for transfering slurries with high erosion and in high densit in high density in industrial sectors as of metallurgy, mining, coal, power generation and environmental protection.

Features:

1. Unique wear-resistance design (structure, material), long service life of wetted parts

2. Wide range of performance, less NPSH, high operational efficiency, and energy-saving

3. Optional combination of wetted parts of different material to meet different working conditions

4. High price/performance ratio, easy maintenance and services

5. Available for multi-stage installation for long distance transfer

6. Various installation forms to meet different site installation conditions and customers' requirements providing pump model selections for clients. Use:

Slurry Pumps are suitable for transfering slurries with high erosion and in high densit in high density in industrial sectors as of metallurgy, mining, coal, power generation and environmental protection.

Features:

1. Unique wear-resistance design (structure, material), long service life of wetted parts

2. Wide range of performance, less NPSH, high operational efficiency, and energy-saving

3. Optional combination of wetted parts of different material to meet different working conditions

4. High price/performance ratio, easy maintenance and services

5. Available for multi-stage installation for long distance transfer

6. Various installation forms to meet different site installation conditions and customers' requirements providing pump model selections for clients. Use:

Slurry Pumps are suitable for transfering slurries with high erosion and in high densit in high density in industrial sectors as of metallurgy, mining, coal, power generation and environmental protection.

Features:

1. Unique wear-resistance design (structure, material), long service life of wetted parts

2. Wide range of performance, less NPSH, high operational efficiency, and energy-saving

3. Optional combination of wetted parts of different material to meet different working conditions

4. High price/performance ratio, easy maintenance and services

5. Available for multi-stage installation for long distance transfer

6. Various installation forms to meet different site installation conditions and customers' requirements providing pump model selections for clients.