6/4E horizontal slurry pumps

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Tianjin,Qingdao,Guangzhou |

| Payment Type: | L/C,T/T,Paypal,Money Gram,Western Union |

| Incoterm: | FOB,CFR,CIF,EXW,FAS,FCA,CPT,CIP,Express Delivery |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean,Land,Air,Express,Express |

| Port: | Tianjin,Qingdao,Guangzhou |

Model No.: 6/4e-ah

Brand: NaiPu

Product Feature of Horizontal Slurry Pumps, AHZJ series:

Wear resistant metal Wet End Parts, long service life.

High efficiency

High head

Discharge branch can be positioned at intervals of 45 degrees

Can be installed in multistage series

Easy to maintain

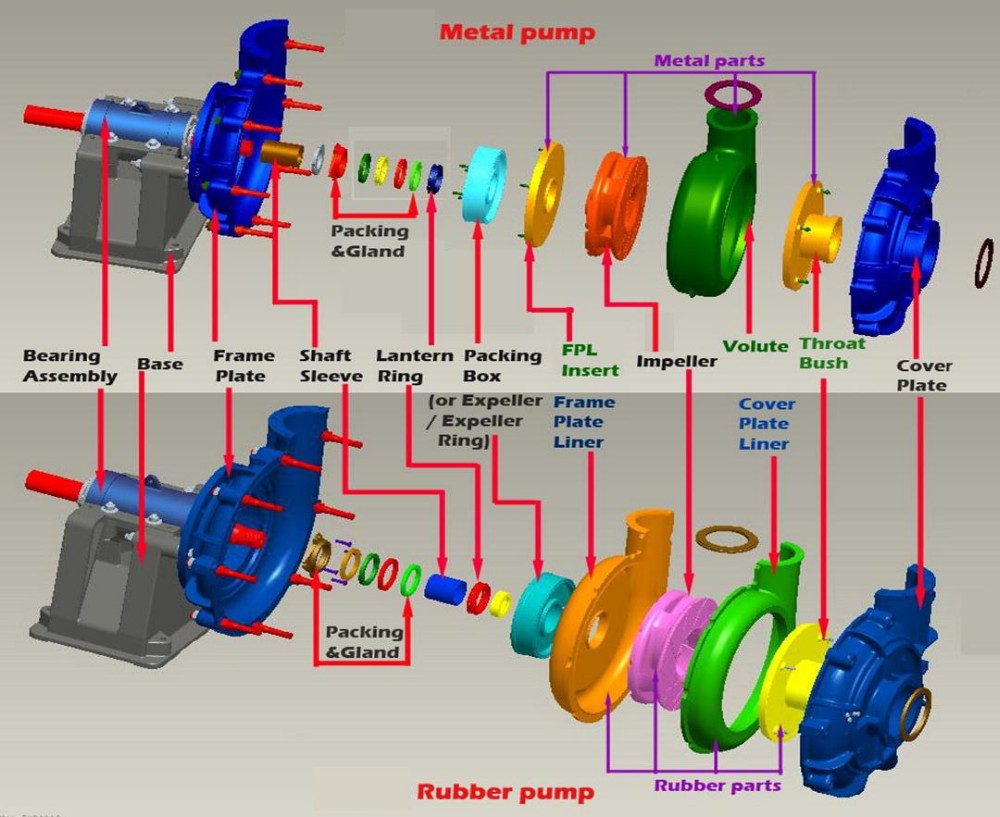

Metal Lined Pump Rubber Lined Pump No Parts Name Materials No Parts Name Materials 1 Liner 27.5% UltraChrome Alloy 1 Frame Plate QT500-7 2 Frame Plate QT500-7 2 Expeller Ring 27% High Chrome Alloy 3 Frame Plate Liner Insert 27.5% UltraChrome Alloy 3 Gland Assembly HT200 4 Cover Plate QT500-7 4 Shaft Sleeve 420 Stainless Steel 5 Throat Bush 27.5% UltraChrome Alloy 5 Expeller 27% High Chrome Alloy 6 Impeller 27.5% UltraChrome Alloy 6 Frame Plate Liner Rubber Coated High Tensile Steel 7 Expeller Ring 27% UltraChrome Alloy 7 Impeller Rubber Coated High Tensile Steel 8 Shaft Sleeve 420 Stainless Steel 8 Cover Plate Liner Rubber Coated High Tensile Steel 9 Expeller 27% HighChrome Alloy 9 Cover Plate QT500-7 10 SKF/Timken (Standard)

Applications for Mining Slurry Pump include:

| · Mill Discharge · Mineral Concentrate · Coarse Tailings · Fine Tailings · Flotation | · Mineral Sands · Dense Media · Coal / Fly Ash · Constructions · Aggregates | · Coarse Sand · Process Water · Oil Sands · Dredging |

Parts material of mining Slurry Pump ( Coarse Tailings Slurry Pumps/fine tailings slurry pump, mining flotation slurry pump):

1.Impeller,cover plate liner,FPL insert:high chrome.

2.Frame plate and pump cover:HT200 or QT500-7.

3.Expeller and expeller ring:gray iron or high chrome.

4.Frame,stuffing box and gland assembly:HT200.

5.Intake joint and discharge joint: natural rubber.

6.O-ring:butadiene-acrylonitrile rubber;

7.Sealing ring:butyl rubber.

8.Shaft sleeve and shaft spacer:3Cr13;

9.Lantern ring:1Cr18Ni9Ti.

Construction features of Coarse Tailings Slurry Pumps/fine tailings slurry pump, mining flotation slurry pump

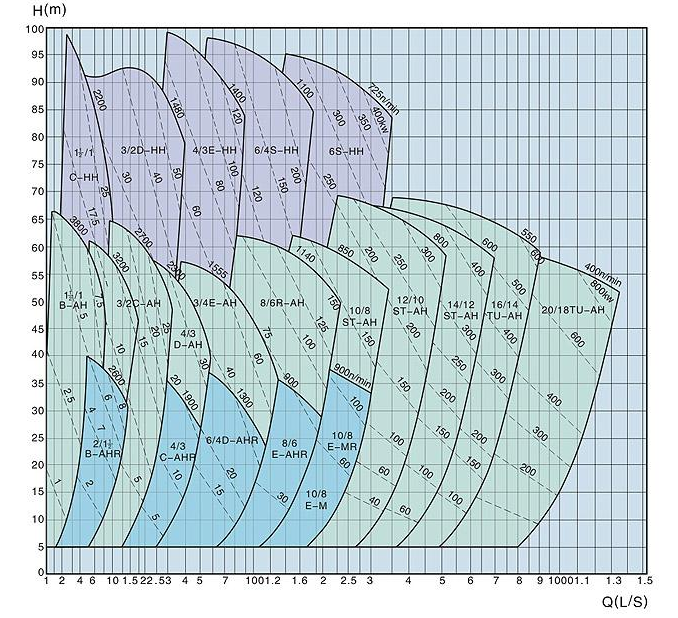

Select chart of Coarse Tailings Slurry Pumps/fine tailings slurry pump, mining flotation slurry pump

Production process of Coarse Tailings Slurry Pumps/fine tailings slurry pump, mining flotation slurry pump

AH Coarse Tailings Slurry Pumps/fine tailings slurry pump, AH mining flotation slurry pump

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.