65 zjw Filter Press Feeding Pumps

Cantilevered horizontal centrifugal slurry pumps/rubber lined slurry pumps/R55 slurry pumps /gland seal slurry pumps/centrifugal seal slurry pumps/wear resistant rubber slurry pumps/ interchangeable slurry pumps/Coal washing slurry pumps/Sand and gravel handling slurry pumps /Effluent handling slurry pumps /minerals flotation processing pumps/coal washing pumps/Feeding Pumps

Naipu® NP-ZJW series filter press Feeding Pump accept unique hydraulic desin and installation mode of the

impeller,ensure that its pump performance curve be more steep than normal pumps,is more suitable to use in the

filter press feed varies according to the changes of the resistance in order to realize the large capacity,

low pressure feeding and low capacity,high pressure filter.The pump is widely used in the coal washery,

environmental protection,aluminum factory,smelting plant etc.

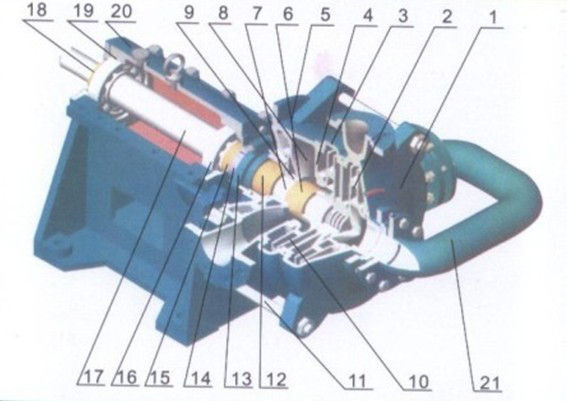

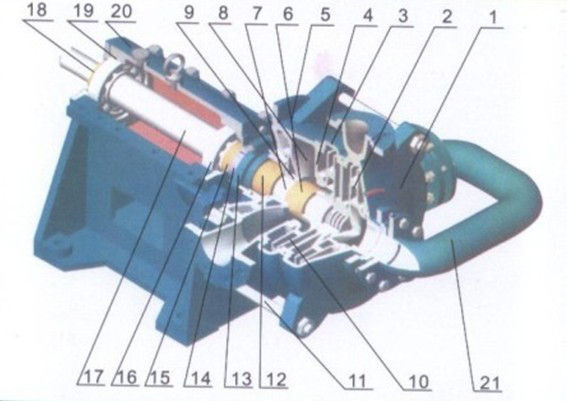

Construction Drawing

The structure chart of the feeding pump

1.Two-phase volute 2.Two-phase impeller

3.One-phase volute 4.Back plate

5.Feeding room 6.Locating bush

7.Expeller 8.Expeller cover plate

9.Decompression body 10.One-phase impeller

11.Tie-bar 12.Shaft sleeve

13.Cover plate 14.Disassembly ring

15.Water retaining plate 16.Bearing

17.Shaft 18.Bearing spacer sleeve

19.Bearing cover 20.Frame

21.Bent pipe

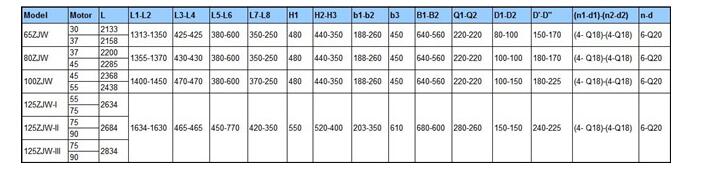

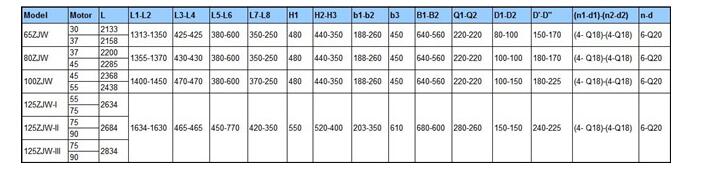

NP-ZJW PUMP SELECTION CHART

NP-ZJW FEEDING PUMP PERFORMANCE PARAMETERS

Product Overviews:

Possible Faults and Settlements.

| Faults | Reason | Settlement |

| 1.Pump fails to discharge any water,The hand of pressure gauge beat violently | 1.Suction pipe don`t have enough water. 2.Suction pipe blocked or the valve is locked. | 1. Inject enough water 2.unlock the inlet valve,clear the blocks 3.Exclude the air leakage |

| 2.The pump can`t discharge water,the hand of vacuum meter beat heavily. | 1.The inlet valve is unlocked or silted up. 2.The resistance of suction pipe is too big or silted up. 3.The height of suction is too high. | 1.Unlock the valve or desilting 2.improve the design of suction pipe or desilt 3.Lower the height of the installation. |

| 3.The pump can`t discharge water,pressure gauge shows heavy pressure. | 1.The resistance of the discharge pipe is too big. 2.The impeller blocked 3.The speed is slow. | 1.Check and adjust the outlet pipe. 2.Clear the impeller 3. Improve the speed. |

| 4.The pump doesn`t rotate | The volute is silted up by the blocks. | Clear the blocks |

| 5.The capacity is not enough | 1.The blocks of the impeller or the inlet or outlet pipe. 2.The abrasion of the impeller is heavily. 3.The speed is low to normal 4.Pump is installed unreasonably or the leakage of the inlet pipe. 5.The transporting height is too high,the loss of the resistance of the inside pipe are too big. 6.The inlet valve not open enough or blocked 7.The packing seal leaks | 1.Clear the impeller or pipe. 2.Change the impeller 3.Adjust the speed 4.Install again or stop leaking. 5.Decrease the height of the transport or reduce the resistance. 6.Unlock the inlet valve 7.Compress the packing tightly |

| 6.The motor of the pump is overloaded | 1.The head of the pump exceeds the head of the working condition. 2.Not consider the slurry density when selecting the pump. 3.The packing press tightly | 1.Turn down the outlet valve,cut the impeller or lower the speed. 2.Select the motor again. 3.Adjust the the screw of the packing gland |

| 7.Abnormal sound in the pump, and no water out | 1.The resistance of the inlet pipe is too big. 2.The height of the suction is too high. 3.Cavitation occurred 4.there is air in the inlet 5.The temperature of the liquid is too high | 1.Clear the suction pipe and sluice valve. 2.Lower the height of the suction 3.Adjust the water valve and let the pump operate in the defined limits. 4.Block the leakage. 5.Lowering the liquid temperature. |

| 8.pump vibrates | 1.pump cavitate 2.The block of the impeller single vane 3.The no concentricity between the pump shaft and motor shaft 4.Fasteners or foundation loose | 1.Adjust the water valve ,lower the height of the installation,reduce the resistance of the inlet. 2.Clear the impeller 3.Alignment again 4.Fasten the screw,and reinforce the foundation. |

| 9.Bearing is overheat | 1.lock the cooling water 2.lubrication is not good. 3.the lubrication oil is not clear 4.the wrong direction of the thrust bearing. 5.there is something wrong with the bearing. | 1.Open the cooling water 2.Adjust the oil quantity 3.Clear the shaft,change oil 4.According to the inlet pressure,adjust the direction of the thrust bearing. 5.Change the bearing |

| 10.Packing short life | The material of packing is not good | Change the packing |

| 11.pump leak oil | 1.High oil level 2.The rubber parts invalid 3.Assembly problem | 1.Lower the oil level 2.Change rubber spares 3.Adjust the assembly |

| 12 Pump head leaking | 1.The rubber parts not press well | Assembly again or press tightly |

FAQ:

Q1. Are you a manufacturer factory?

Yes,we are the direct manufacture factory,and have more than 10 years' experience in this area.

Q2.Do you have stock products to sell?

Some we have in stock ,but the others not. Since we always produce these products according to customers requirements.

Q3.What advantages do you have?

A: We are direct manufacturer and the price is competitive.

B: Our engineer are very experieced in this area, and we can do OEM service to you.

C:We are factory, and we can arrange production schedule,so as to punctual delivery.

Contact Details:

Shijiazhuang Naipu Pump Co.,Ltd.

Add:No.368 Xinshi North Road,Shijiazhuang Hi-Tech Industry Development Zone, Hebei,China,050091.

Tel:0086-311-897162903

Fax:0086-311-87162902

Contact Person: Karen Tan

Skype: karen_naipump