14/12 T-G Sand Suction Dredging Pump

Features

1.The G series sand and Gravel Pump is a single-suction Slurry Pump that allows the slurry to be sucked in from only one suction side.Available with one impeller,the single-stage horizontal cantilever pump is widely used in dredging,mining and mineral processing industries.

2.A typical feature of this sand and gravel pump is its one-piece case.Other desiable features include the generous passage and abrasion-resistant wet-end parts made from high chrome.

3.Shaft seal options:packing gland seal,expeller seal and mechanical seal.

4.The discharge outlet has 8 positions at 45 degree intervals that can be selected to meet the installation and application requirements.

Advantages

1.Optimized slurry pump system layout simplifies maintenance operation,ensures long service life,and suit the pump for heavy duty tasks of pumping slurries with large solids.

2.One-piece case and wear-resistant hydraulic parts are easy to replace and repair.

3.Wide flow passage allows a large volume of slurry to pass.The sand and gravel pump is specially designed to handle high-abrasion applications that ordinary pumps can't even attempt.

4.The pump head is fixed to the mounting base by a few bolts.Users can adjust the clearance between the impeller and suction liner from underneath a bearing pedestal.

5.Shaft seal options:packing gland seal,centrifugal seal and mechanical seal.Users can easily replace one type of seal with another in order suit the specific pumping application.

Hydraulic Modeling

Wet-end components are cast of hard metal or polyurethane. They are able to maintain good hydraulic performance even when the dredging pump is subject to severe wear.This helps the sand and gravel pump achieve optimal levels of pumping efficiency for an extended period,3-vane impeller improves the pump's ability to pass the slurry.

Shaft Seals

Packing Seal

As one of the most commonly used seals for rotating shafts,the gland seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing.This kind of seal is suitable for use in almost all pumping applications.In situations where corrosive solids or high temperature might be encountered,aramid fiber is used as packing material for the gland.To further increase the shaft's resistance to abrasion,a ceramic coated shaft sleeve would be used.

Centrifugal seal-expeller

The combination of impeller and expeller creates the pressure needed to seal against leakage.Together with the gland seal or lip seal which is used as the shut-down seal,this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site,or sealing water is allowed to enter inside the pumping chamber to dilute the slurry.

Mechanical seal

Advances in sealing technology allows us to create a mechanical seal that ensures zero leakage. Catridge type mechanical seal facilitates installation and replacement.Other types of mechanical seal are among options to suit the sand and gravel pump for various pumping applications.We also utilize special ceramic and alloys of high strength and hardness on parts that are subjected to friction.Unique design of and seamless fit between the mechanical seal and seal chamber provides excellent resistance to abrasion and shock that ensures its effectiveness under the toughest conditions.

Dredging Pumps Clear Water Performance

| Capacity(m3/h) | Head (m) | Impeller Speed(r/min) | Efficiency(%) | Inlet Dia.(mm) | Outlet Dia.(mm) | NPSHR | Max diameter of flowed particle(mm) |

| five pieces | three pieces |

| 100WS | 180-250 | 25-45 | 1000-1400 | 50-58 | 150 | 100 | <3.5 | 50 | 82 |

| 150WS | 250-550 | 20-40 | 1200-1400 | 58-60 | 200 | 150 | <4 | 76 | 127 |

| 150WSG | 350-700 | 40-65 | 800-980 | 68-71 | 200 | 150 | <3.5 | 84 | 140 |

| 200WS | 350-700 | 20-45 | 700-980 | 60-65 | 250 | 200 | <4.5 | 105 | 178 |

| 200WSG | 550-1000 | 40-65 | 700-850 | 70-72 | 250 | 200 | <4 | 108 | 180 |

| 250WS | 700-1100 | 20-45 | 500-750 | 65-70 | 300 | 250 | <4 | 132 | 220 |

| 250WSG | 900-1500 | 40-60 | 500-650 | 70-74 | 350 | 250 | <4.5 | 86 | 144 |

| 300WS | 1100-1800 | 20-40 | 400-600 | 65-68 | 350 | 300 | <4.5 | 144 | 241 |

| 300WSG | 1500-2200 | 30-65 | 400-550 | 74-78 | 450 | 300 | <4 | 144 | 241 |

| 350WSG | 2000-3000 | 40-65 | 400-550 | 74-78 | 450 | 350 | <4 | 147 | 245 |

| 450WSG | 3000-4000 | 35-67 | 350-500 | 76-80 | 600 | 450 | <4.5 | 125 | 254 |

| 500WSG | 4000-5500 | 40-65 | 350-450 | 78-80 | 650 | 500 | <4.8 | 150 | 250 |

| 600WSG | 5000-9000 | 55-80 | 320-400 | 81-85 | 650 | 600 | <6 | 160 | 220 |

| 700WSG | 8000-12000 | 60-85 | 280-380 | 83-85 | 750 | 700 | <6 | 180 | 280 |

| 800WSG | 10000-15000 | 50-70 | 260-360 | 79-80 | 850 | 800 | <6 | 200 | 300 |

| 900WSG | 12000-19000 | 50-75 | 280-330 | 83-85 | 950 | 900 | <6 | 210 | 320 |

| 1000WSG | 16000-25000 | 23-76 | 180-290 | 85-87 | 1100 | 1000 | <6 | 230 | 350 |

Portable Gravel Dredge Pumps / Mining Slurry Pumps /GH Gravel Pumps /Gravel Pumps /Sand Pumps /Dredging Slurry Pumps /Horizontal Dredging Pumps /Submersible Dredging Pumps/ River Sand Dredging Pumps/Portable Dredge Pumps /Dredge diesel booster pumps.

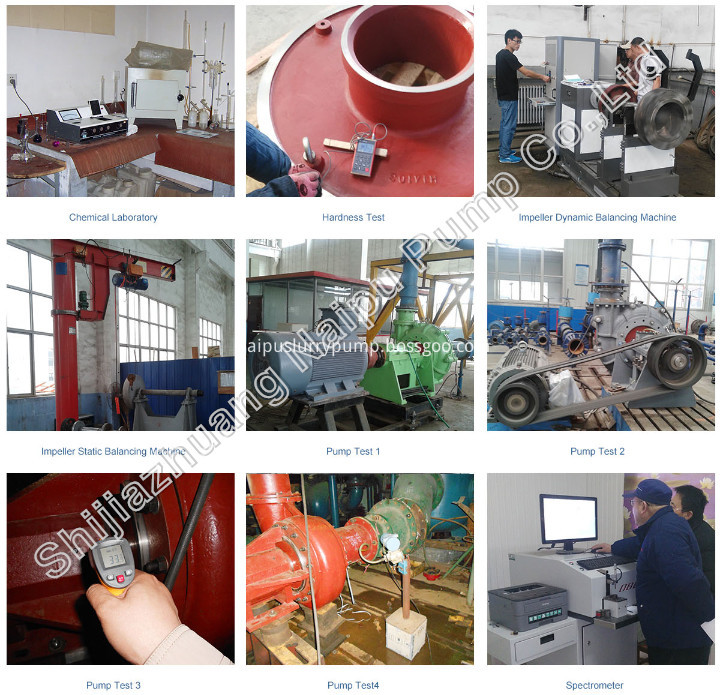

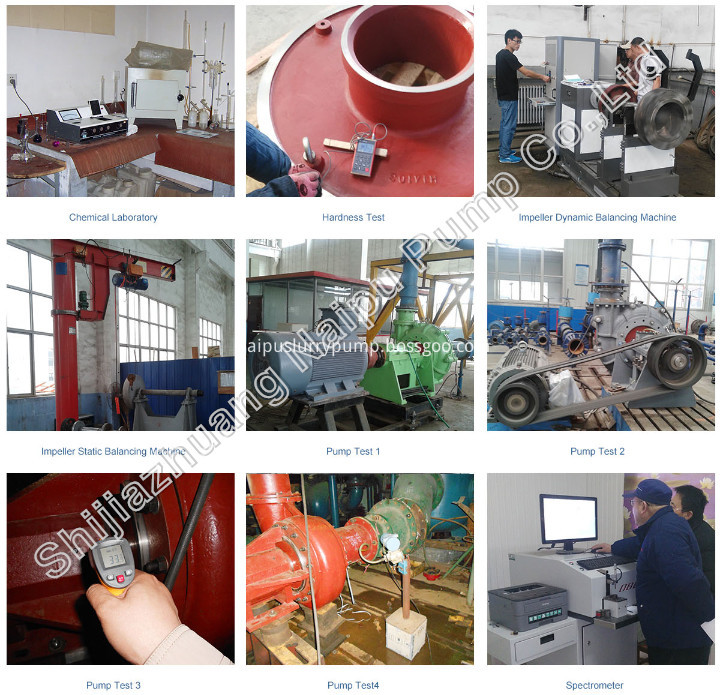

Workshop Photos:

NAIPU PUMP is a whole processing company, Start from Modeling Workshop,Casting Workshop,Heat treatment Workshop,Machining Workshop ,Assembly Workshop and Pump Testing Workshop are all by us. So we are modernization and integrated company to satisfy the requirement of the changing needs of market.

Quality Control:

As a professional pump manufacturer,we always stick to the principle of technology and quality comes first. At NAIPU PUMP, we strictly adhere to the ISO9001 Standard and CE Certificate and other industry standards as requests.

We set various check points along the whole production line,which throughout Raw Material,Charging Material,Surface and Heat Treatment checking,Material Analysis,Spare Testing and Pump Testing etc.

We have established a strict QA and QC system,we can provide quality control records such as “Spectrum Detection” “Metallographic Microscope Inspection” “Block Test” “Ultrasonic Flaw Detection” “ Penetration Testing”etc. And related test reports to our clients if necessary, such as “ Material Test Report ” “ Dimensional Test Report ” “ Rotor Balancing Test Report ” “ NDT Test Report ” “ Hardness Inspection Report ” etc.

Working At Site:

Our Pumps mainly used in the below applications,

Heavy Mining | Mineral Processing | Sand and Gravel |Coal Prep | Cyclone Feeds | Aggregate Processing | Fine Primary Mill Grinding | Chemical Slurry Service | Tailings | Secondary Grinding | Industrial Processing | Pulp And Paper | Food Processing | Cracking Operations | Ash Handling | Pipeline Transport | High Velocity Hydraulic Transport |Food Processing | Explosive Sludge In Metal Smelting | River And Pond Dredging | Heavy Refuse Removal | Larger Particle Or Low NPSHA Applications | Continuous (Snore) Sump Pump Operation | Abrasive Slurries | High Density Slurries | Large Particle Slurries | Sump Drainage | Wash down | Floor Drainage | Mixing | Iron Ore | Cooper | Diamond | Alumina | Coal | Gold | Kaolin | Phosphorite | Steel | Palm | Suger | Chemical | Power | FGD | Frac Sand Blending | Construction | City Sewage | etc.

Contact US

Shijiazhuang Naipu Pump Co.,Ltd

Add:No.368 Xinshi North Road,Shijiazhuang Hi-Tech Industry Development Zone Hebei,China,050091.

Contact Person:Karen Tan

Skype: karen_naipump.

If you have any query about pumps, please don't hesitate to contact us.