10/8F-G Suction Hopper Dredging Pumps

Coal washing sand gravel pumps/delivering slurries in mining gravel pumps/dredging in dredger pumps/river sand dredger gravel pumps/gravel pumps/mining slurry pumps /Sand gravel pumps on dredger boat

Naipu® NP-G series of Dredge and Gravel pumps is designed specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Capable of handling large particles at consistently high efficiencies results in low cost of ownership. The large volume internal profile of the casing reduces associated velocities further increasing component life.

Typical Applications--- Slag Granulation Suction Hopper Dredging Dredging Barge Loading Sand Reclamation Sugar Beet

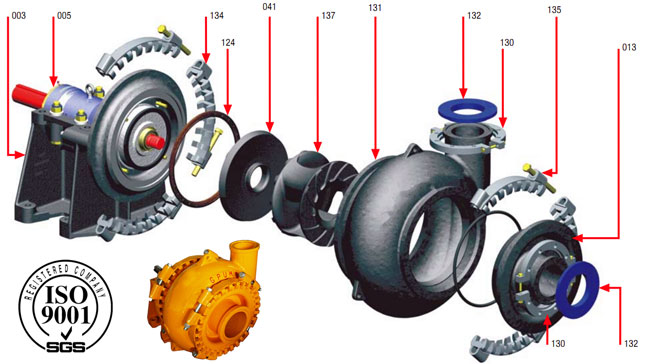

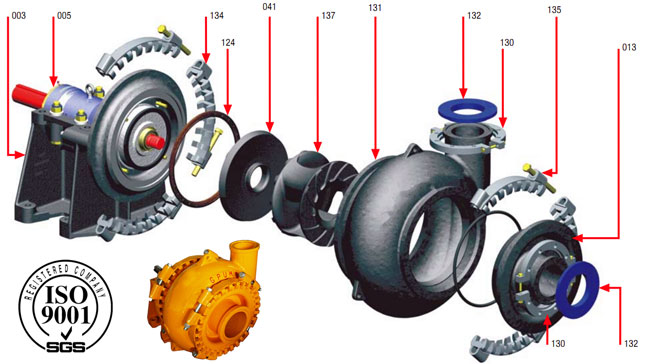

NP-G Construction Drawing--

Main Part Number At The Drawing

003:Base 005: Bearing Assembly 132:Intake Joint Discharge Joint 130:Discharge Flange Intake Flange 013:Cover Plate | 131:Bowl

137:Impeller

041:Back Liner

135:Door Clamp Ring

134: Adapter Plate Clamp Ring

124:Volute Cover Seal |

Materials of Construction

| | VOLUTE | IMPELLERS | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS |

| Standard | High Chrome Alloy | High Chrome Alloy | Cast Iron | Chrome Alloy

or

SG Iron | Chrome Alloy

or

SG Iron | SG Iron | Natural Rubber |

| Options | SG Iron | SG Iron | Mild Steel

Fabricated | SG Iron | SG Iron | EN56C

Ferralium

Hasteloy C

Ceramic

Stellite

Chrome Oxide | Nordel

Neoprene

Viton

Butyl

EPDM |

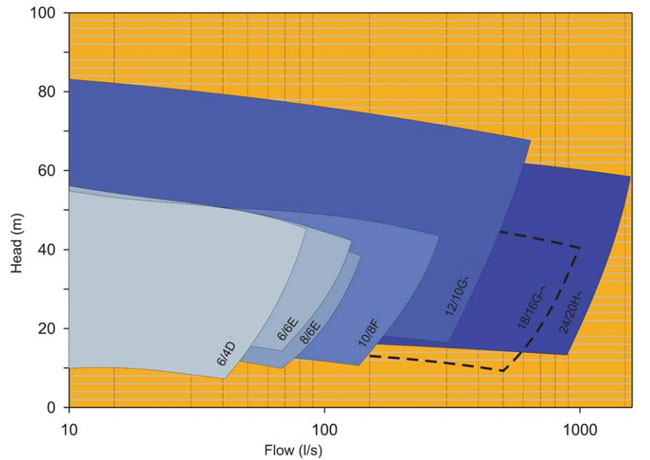

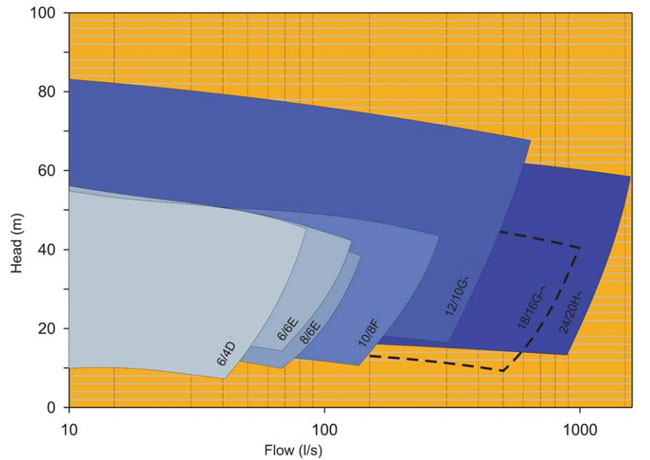

NP-G Gravel Pump SELECTION CHART

NP-G Slurry Pump PERFORMANCE PARAMETERS

| Model | Flow(m3/h) | Head(m) | Speed(r/min) | Efficiency(%) | NPSHr/m | Max permissible particle size/mm |

| 6X4D-NP-G | 187-36 | 7-51 | 1400-600 | 30-58 | 1.5-3.7 | 82 |

| 8X6E-NP-G | 576-133 | 10-48 | 1400-800 | 60-54 | 1.2-4.2 | 127 |

| 10X8F-NP-G | 930-216 | 11-44 | 940-500 | 65-34 | 3-7 | 178 |

| 12X10G-NP-G | 1512-360 | 11-58 | 850-400 | 70-50 | 1.5-6 | 220 |

| 14X12G-NP-G | 3168-522 | 9.5-66 | 700-300 | 68-60 | 2-8.5 | 241 |

| 16X14TU-NP-G | 3024-900 | 14-45 | 500-300 | 70-50 | 3.5-6.5 | 254 |

| 10X8F-NP-GH | 1091-324 | 19.2-56.5 | 800-500 | 72-60 | 1.5-5 | 180 |

| 12X10G-NP-GH | 2232-612 | 28-77 | 700-450 | 73-60 | 1.5-8 | 210 |

Coal washing sand gravel pumps/delivering slurries in mining gravel pumps/dredging in dredger pumps/river sand dredger gravel pumps/gravel pumps/mining slurry pumps /Sand gravel pumps on dredger boat

NP-G Gravel Pump Photos

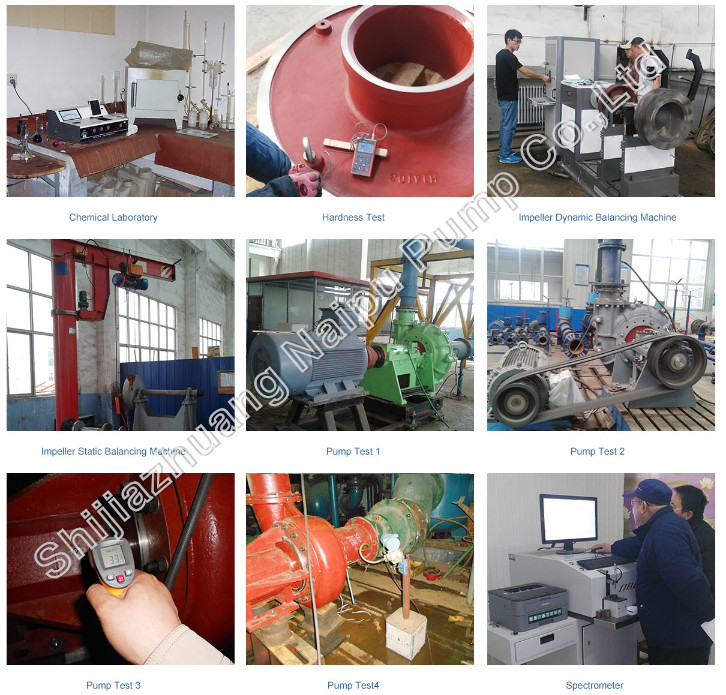

Workshop Photos

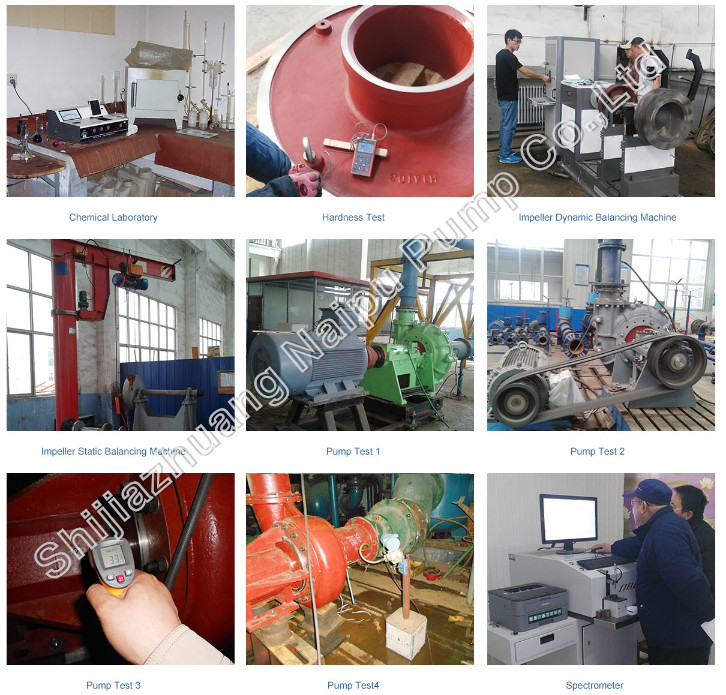

Quality Control

FAQ:

1. Q: What's your factory workshops ?

A: Our factory manufacture include casting, machining process, lathe process, heat treatment, assembly, test and packaging etc.

Warmly welcome to visit & inspect our factory any time.

2.Q: Could you help us if we don't know which pump model we need ?

A: Yes, please tell me your detail requirements, Such as capacity , head ,solid density etc.

3.Q: How about your price?

A: We are sure our price is factory price, and are of high quality for our long term cooperation.

4. Q: What is your Slurry Pump material ?

A: slurry pump material high chrome alloy or rubber, super abrasive-resistant metal.

Shaft material is stainless steel alloy.

5. Q:How does your factory do regarding quality control?

A:Quality is priority. Our factory has 15~30 QC.We always attach great importance to quality controlling from the very beginning to the very end.

6. Q: Is it easy for customers to change the parts by themselves ?

A: Yes, the structure is simple ,customers can change it very easily. We will also supply you maintenance tools for free.

7. Q: How to do if the pump or parts have operation problem within the warranty?

A: Tell me details and show me pictures, we will send you solution at once without any hesitation.

Contact Details:

Shijiazhuang Naipu Pump Co.,Ltd

Contact: Karen Tan

Skype: karen_naipump

If you have any query,please feel free to contact me freely.