65ZJL Neoprene Lined Vertical sump pumps

Vertical sump pumps/centrifugal slurry pumps/vertical pumps delivering abrasive slurries/sump pumps/abrasion-resistant metal sump pumps/65qv sump pumps/100RV sump pumps/vertical pumps transporting non-edge angle abrasive slurry.

Naipu® NP-SP pumps are vertical, centrifugal slurry pumps submerged in sump to work.They are designed for delivering abrasive,large particle and high density slurries.These pumps have no need of any shaft seal and sealing water. They can also be operated normally for insufficient suction duties.Wet parts of type NP-SP pump are made of abrasion-resistant metal. All parts of type NP-SP(R) pump immersed in liquid are lined with rubber outer liner.They are suited to transport non-edge angle abrasive slurry.

Features

1.Submersed in water and sitting on the bottom of the sump,the SP series Vertical Sump Pump is commonly used to convey high-viscosity slurries with highly abrasive,coarse particles.

2.A key feature of this sump pump is the one-piece pump housing.Wet-end parts are replaceable and made of high-chrome for maximum corrosion resistance.Rubber and polyurethane are selected to make the pump liner and impeller.The sump pump can be used for different pumping applications.

3.Various types of impellers are designed to handle different pumping tasks.

4.Vertical cantilever design eliminates the need of shaft seal or sealing water.

5.Parts submerged in the slurry can be made of metal or rubber.

Advantages

1.The phydical layout of the submersible sump pump simplifies maintenance operations.

2.The sump pump body is bolted to the support plate.On top of the support plate sits the Bearing Assembly.Closer to the pump end is a double-row tapered roller bearing.Connected to the drive end is a single-row cylindrical roller bearing.

3.Installed on the bearing assembly is a motor support frame,or motor mounting base, where the motor is mounted.Flexible coupling or drive belt connects the motor shaft and the pump shaft.

4.Without any shaft seal or sealing water,the centrifugal sump pump can function properly even when there is insufficient slurry getting to the suction side.

5.A screen filter is set at the suction side to separate large particles out of the slurry.

Installation Types

DC: The motor mounting base is set above the bearing assembly,so it is easy to replace or repair the motor parts.

BD: A V-belt is used to connect the motor shaft and the pump shaft.The motor support frame is installed above the bearing assembly,allowing easy replacement of grooved wheels.The purpose of swapping grooved wheels is to change the rotary speed of the pump shaft in order to suit varing pumping applications or conform to the worn-down sump pump.

Typical Applications--- Sump drainage washdown Floor drainage Mill sumps Carbon transfer Monitoring Magnetite mixing

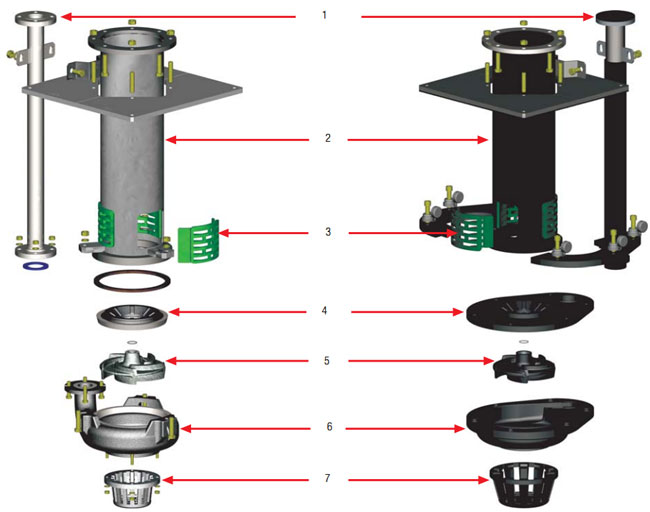

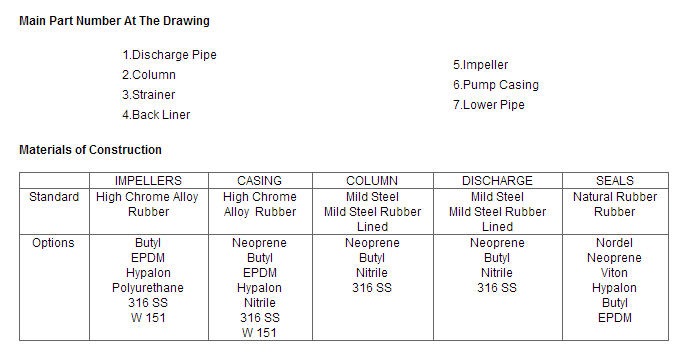

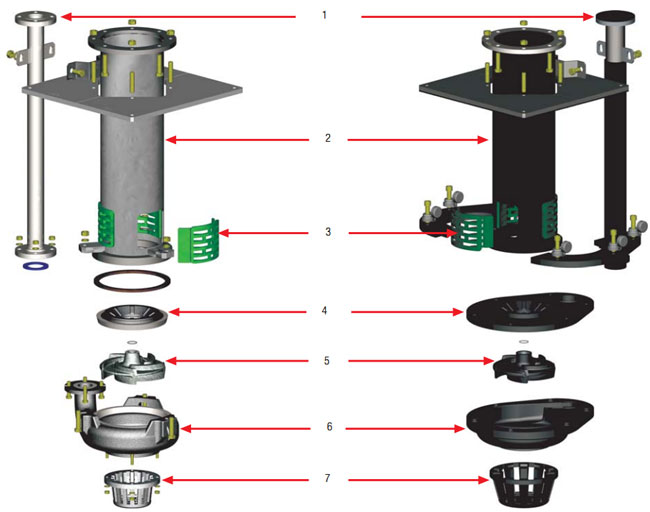

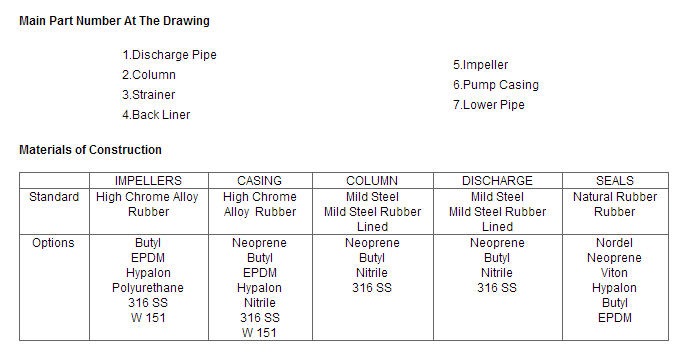

NP-SP(R) Sump Pump Showing Component

Vertical sump pumps/centrifugal slurry pumps/vertical pumps delivering abrasive slurries/sump pumps/abrasion-resistant metal sump pumps/65qv sump pumps/100RV sump pumps/vertical pumps transporting non-edge angle abrasive slurry.

| Type | Allowable Mating Max. Power(Kw) | Range Of Performance | Impeller |

| Capacity/Q | Head/m | Speed/rpm | Max Efficiency/% | No. of Vanes | Impeller Diameter/mm |

| m³/hr | L/S |

| 40PV-NP-SP | 15 | 19.44-43.2 | 5.4-12 | 4.5-28.5 | 1000-2200 | 40 | 5 | 188 |

| 65QV-NP-SP | 30 | 23.4-111 | 6.5-30.8 | 5-29.5 | 700-1500 | 50 | 5 | 280 |

| 100RV-NP-SP | 75 | 54-289 | 15-80.3 | 5-35 | 500-1200 | 56 | 5 | 370 |

| 150SV-NP-SP | 110 | 108-479.16 | 30-133.1 | 8.5-40 | 500-1000 | 52 | 5 | 450 |

| 200SV-NP-SP | 110 | 189-891 | 152.5-247.5 | 6.5-37 | 400-850 | 64 | 5 | 520 |

| 250TV-NP-SP | 200 | 261-1089 | 72.5-302.5 | 7.5-33.5 | 400-750 | 60 | 5 | 575 |

| 300TV-NP-SP | 200 | 288-1267 | 80-352 | 6.5-33 | 350-700 | 50 | 5 | 610 |

Product Overview:

Workshop photos:

Shijiazhuang Naipu Pump Co.,Ltd is a professional manufacturer of Slurry Pumps,

We can be in service from Mould ,Casting, Heat treatment ,Machining, Assembly,Testing etc. one dragon service.

We have our Mould Workshop,there are Wooden Mould,Aluminum Mould,Lost Foam Casting Mould,Wax Mould etc.

Naipu own Casting Workshop,mainly Sand Casting and Lost Foam Casting and Precision Casting.

Naipu own Heat treatment Workshop, after out of furnace,the hardness are according to the technical requirement.

Naipu own Machining Workshop,we are professional from rough machining to finish machining.

Naipu own Assembly Workshop, our mechanicians are skilled in assemblying as we had about 30 years experience in this area.

Naipu own Inspection Workshop, Every order every parts we will do the test before delivery.

Quality Control Plans:

As a professional pump manufacturer,we always stick to the principle of technology and quality comes first. At NAIPU PUMP, we strictly adhere to the ISO9001 Standard and CE Certificate and other industry standards as requests.

We set various check points along the whole production line,which throughout Raw Material,Charging Material,Surface and Heat Treatment checking,Material Analysis,Spare Testing and Pump Testing etc.

CONTACT US:

SHIJIAZHUANG NAIPU PUMP CO.,LTD

ADD:NO.368 XINSHI NORTH ROAD,SHIJIAZHUANG HI-TECH INDUSTRY DEVELOPMENT ZONE HEBEI,CHINA 050091.

CONTACT PERSON:KAREN TAN

SKYPE: KAREN_NAIPUMP

PLEASE CONTACT ME FREELY IF ANY QUESTIONS.