Medium duty slurry pumps

Cantilevered slurry pumps /horizontal centrifugal slurry pumps/slurry pumps handling highly abrasive slurries/coal mine slurry pumps/wear-resistant metal liner slurry pumps /mechanical seal slurry pumps/expeller seal slurry pumps

Naipu® NP-M series centrifugal slurry pumps and spare parts could fully interchange with world famous brand.These pumps are of heavy-duty construction, designed for continuous pumping of highly abrasive and corrosive slurries. They feature a wide choice of replaceable abrasion resistant metal casting liners and Impellers, which are all interchangeable within a common casting assembly.

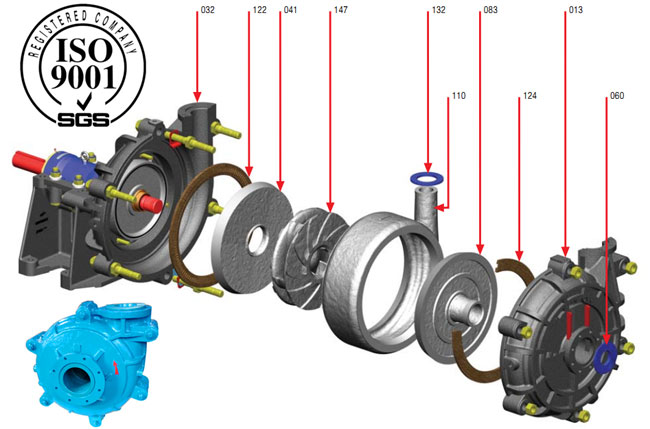

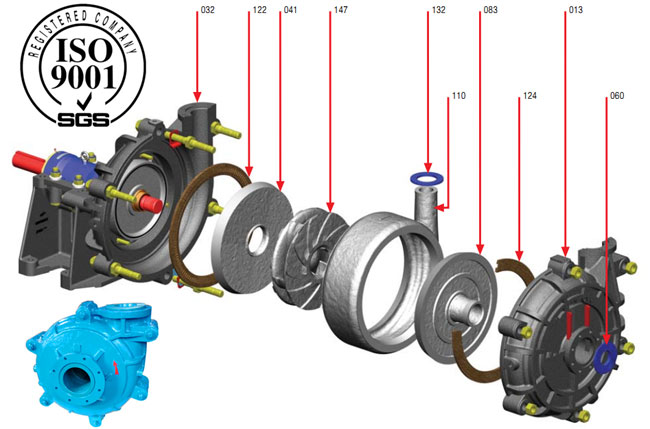

Structure:

The frame plates of this kind of Slurry Pump have replaceable wear-resistant metal liners. The impellers are made of wear-resistant metal. The frame plate liner and impeller for M slurry pump are adoptable of hard metal only.

Bearing Assembly of this kind of slurry pump use cylindrical structure, adjusting the space between impeller and front liner easily, being removed completely when being repaired. Bearing assembly use grease lubrication.

The shaft seal of this kind of slurry pump could use the packing seal, expeller seal and mechanical seal. The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.

Here are the drive types, such as V belt drive, gear reducer drive, fluid coupling drive, and frequency conversion drive devices. The pump of this type may be installed in multistage series to meet the delivery for long distance.

Typical Applications---

Dense media transfer

Dense media make-up

Bottom boiler and fly ash

Ferrosilicon make up

Thickener underflow

Dewatering

| NP-M Slurry Pump Performance Parameters |

| Type | Allowable Matching max.power (kw) | Clear Water Performance | Impeller |

| Capacity/Q m3/h | Head/m | Speed/rpm | Max.efficiency/% | NPSH/m | Nos of vane | Impeller Dia/mm |

| 10/8E-NP-M | 120 | 540-1228 | 15-61 | 600-1100 | 70 | 4.5-8 | 4 | 549 |

| 10/8R-NP-M | 300 |

Cantilevered slurry pumps /horizontal centrifugal slurry pumps/slurry pumps handling highly abrasive slurries/coal mine slurry pumps/wear-resistant metal liner slurry pumps /mechanical seal slurry pumps/expeller seal slurry pumps

Product Overviews:

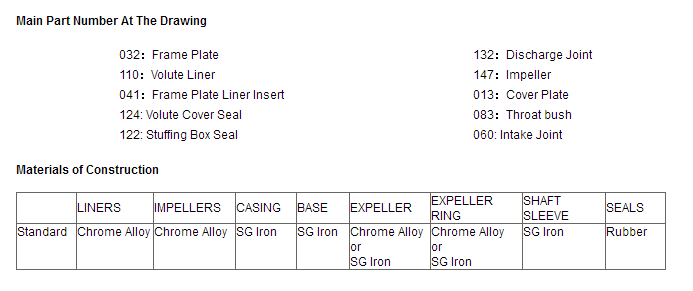

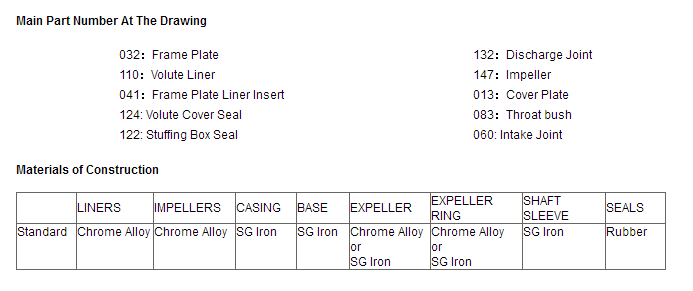

| Metal Lined Pump Material |

| No | Part Name | Materials | No | Parts Name | Materials |

| 1 | Liner | Cr26 High Chrome Alloy | 1 | Frame Plate | QT500-7 |

| 2 | Frame Plate | QT500-7 | 2 | Expeller Ring | Cr26 high chrome alloy |

| 3 | Frame Plate Liner Insert | Cr26 High Chrome Alloy | 3 | Gland Assembly | HT200 |

| 4 | Cover Plate | QT500-7 | 4 | Shaft Sleeve | 420 Stainless Steel |

| 5 | Throat Bush | Cr26 High Chrome Alloy | 5 | Expeller | Cr26 High Chrome Alloy |

| 6 | Impeller | Cr26 High Chrome Alloy | 6 | Frame Plate Liner | Rubber |

| 7 | Expeller Ring | Cr26 High Chrome Alloy | 7 | Impeller | Rubber |

| 8 | Shaft Sleeve | 420 Stainless Steel | 8 | Cover Plate Liner | Rubber |

| 9 | Expeller | Cr26 High Chrome Alloy | 9 | Cover Plate | QT500-7 |

| 10 | Bearing Assembly | SKF /Timken (standard) | | |

|

Naipu Main Pump Types

| Naipu Main Slurry Pump Models |

| NP-AH | NP-HH | NP-SP | NP-G | NP-AF | NP-L | NP-M |

| 1.5/1B-AH(R) | 1.5/1C-HH | 40PV-SP(R) | 6/4D-G | 3QV-AF | 20A-L | 10/8R-M |

| 2/1.5B-AH(R) | 3/2D-HH | 65QV-SP(R) | 8/6E-G | 4RV-AF | 50B-L(R) | 10/8E-M |

| 3/2C-AH(R) | 4/3E-HH | 100RV-SP(R) | 10/8F-G | 6SV-AF | 75C-L | |

| 4/3C-AH(R) | 4/3X-HH | 150SV-SP(R) | 12/10G-G | 8SV-AF | 100D-L | |

| 6/4D-AH(R) | 6/4X-HH | 200SV-SP(R) | 14/12G-G | | 150E-L | |

| 6/4E-AH(R) | 6/4F-HH | 250TV-SP | 14/12T-G | | 300S-L | |

| 8/6E-AH(R) | 6S-H | | 16/14G-G | | 350FF-L | |

| 8/6R-AH(R) | 6S-HP | | 16/14TU-GH | | 450ST-L | |

| 10/8F-AH(R) | 8/6S-H | | 18/16G-G | | | |

| 10/8ST-AH(R) | 8/6S-HP | | 18/16TU-GH | | | |

| 12/10ST-AH(R) | 8/6X-HP | | | | | |

| 12/10FF-AH(R) | | | | | | |

| 14/12G-AH(R) | | | | | | |

| 14/12ST-AH(R) | | | | | | |

| 16/14TU-AH(R) | | | | | | |

| 20/18TU-AH(R) | | | | | |

|

Pump Applications

| Applications |

| Heavy mining | Mineral Processing | Coal Preparation | Cyclone Feeds |

| Chemical Slurry Service | Tailings | Secondary Grinding | Industrial Processing |

| Cracking Operation | Ash Handling | Pipeline Transport | High velocity Hydraulic Transport |

| River and Pond Dredging | Heavy Refuse Removal | Washdown | High density slurries |

| Floor drainage | iron ore | Copper mine | Diamond mine |

| Gold mine | kaolin | phosphorite | steel |

| Chemical | Power | FGD | Frac Sand Blending |

| Aggregate Mining | Pulp and Paper | Food Processing | Fine Primary Mill Grinding |

| Abrasive slurries | Alumina mine | Palm | Construction |

| Food Processing | Explosive in metal smelting | Coal mine | Continuous Sump Pump Operation |

| City Sewage | Sugar | |

|

FAQ:

1. Q: What's your factory workshops ?

A: Our factory manufacture include casting, machining process, lathe process, heat treatment, assembly, test and packaging etc.

Warmly welcome to visit & inspect our factory any time.

2.Q: Could you help us if we don't know which pump model we need ?

A: Yes, please tell me your detail requirements, Such as capacity , head ,solid density etc.

3.Q: How about your price?

A: We are sure our price is factory price, and are of high quality for our long term cooperation.

4. Q: What is your Slurry Pump material ?

A: slurry pump material high chrome alloy or rubber, super abrasive-resistant metal.

Shaft material is stainless steel alloy.

5. Q:How does your factory do regarding quality control?

A:Quality is priority. Our factory has 15~30 QC.We always attach great importance to quality controlling from the very beginning to the very end.

6. Q: Is it easy for customers to change the parts by themselves ?

A: Yes, the structure is simple ,customers can change it very easily. We will also supply you maintenance tools for free.

7. Q: How to do if the pump or parts have operation problem within the warranty?

A: Tell me details and show me pictures, we will send you solution at once without any hesitation.

Contact Us

Shijiazhuang Naipu Pump Co.,LTD.

Contact Person: Karen Tan

Skype:karen_naipump

Add: No.368 Xinshi North Road,Shijiazhuang Hi-Tech Industry Development Zone,Hebei,China,050091.