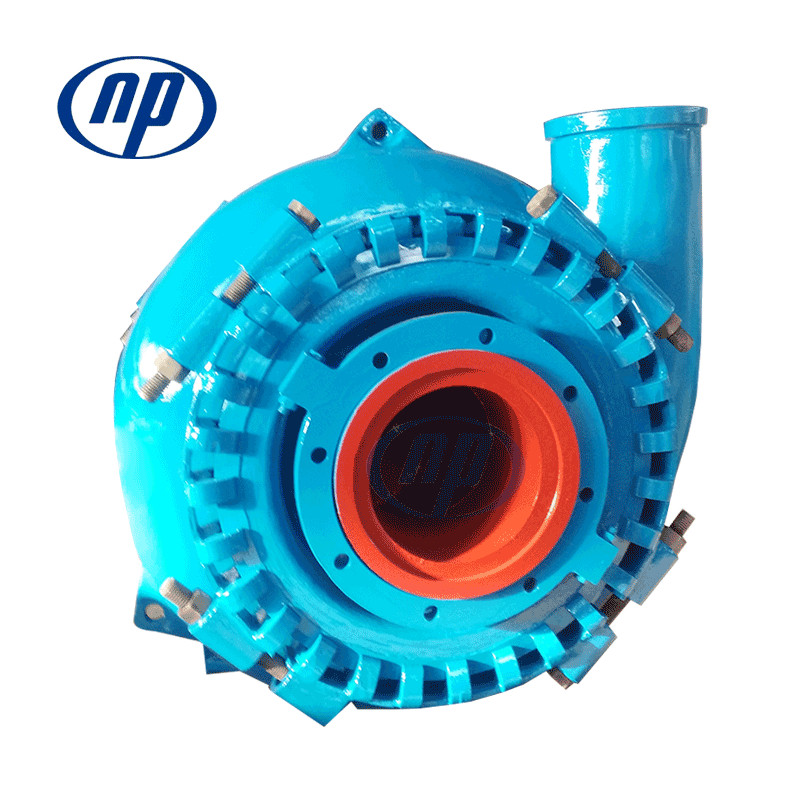

10/8 F-G Sand Mud Suction Dredge Pump

Coal washing sand gravel pumps/delivering slurries in mining gravel pumps/dredging in dredger pumps/river sand dredger gravel pumps/gravel pumps/mining slurry pumps /Sand gravel pumps on dredger boat

Naipu® NP-G series of Dredge and Gravel pumps is designed specifically for continuous pumping of extremely aggressive slurries, with a wide particle size distribution. Capable of handling large particles at consistently high efficiencies results in low cost of ownership. The large volume internal profile of the casing reduces associated velocities further increasing component life.

Typical Applications--- Slag Granulation Suction Hopper Dredging Dredging Barge Loading Sand Reclamation Sugar Beet

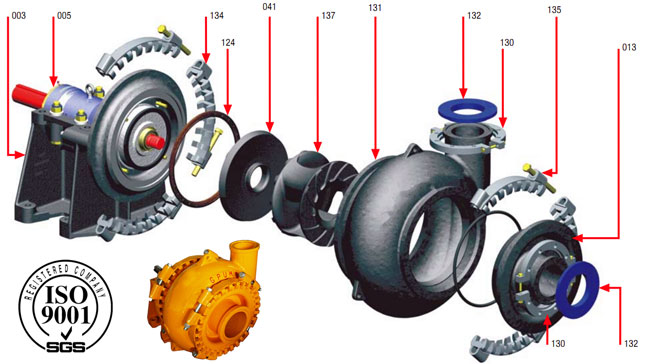

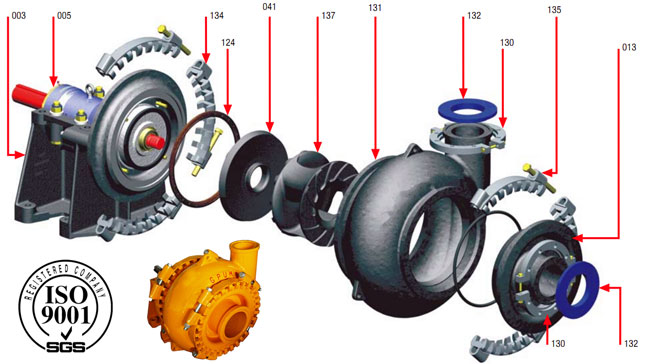

NP-G Construction Drawing--

Main Part Number At The Drawing

003:Base 005: Bearing Assembly 132:Intake Joint Discharge Joint 130:Discharge Flange Intake Flange 013:Cover Plate | 131:Bowl

137:Impeller

041:Back Liner

135:Door Clamp Ring

134: Adapter Plate Clamp Ring

124:Volute Cover Seal |

Materials of Construction

| | VOLUTE | IMPELLERS | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS |

| Standard | High Chrome Alloy | High Chrome Alloy | Cast Iron | Chrome Alloy

or

SG Iron | Chrome Alloy

or

SG Iron | SG Iron | Natural Rubber |

| Options | SG Iron | SG Iron | Mild Steel

Fabricated | SG Iron | SG Iron | EN56C

Ferralium

Hasteloy C

Ceramic

Stellite

Chrome Oxide | Nordel

Neoprene

Viton

Butyl

EPDM |

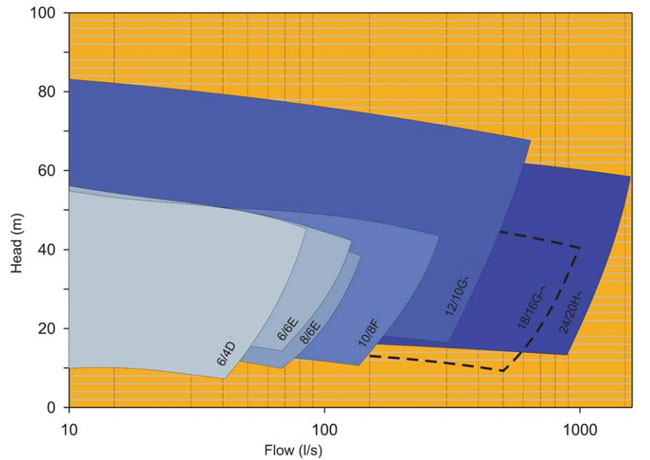

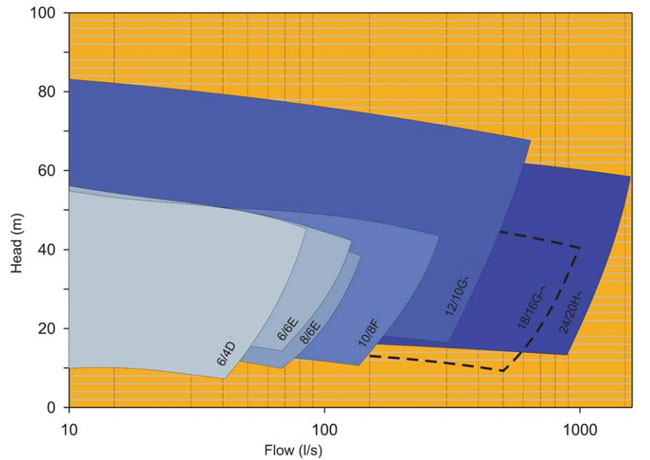

NP-G Gravel Pump SELECTION CHART

NP-G Slurry Pump PERFORMANCE PARAMETERS

| Pump Model | Allowable

Max. Power

(kW) | Clear Water Performance | Max Solid Passing (mm) |

| Capacity Q | Head | Speed | Max.Eff. | NPSH | Impeller |

| m3/h | l/s | H(m) | n(r/min) | η% | (m) | Dia. |

| 6/4D-G | 60 | 36-250 | 10-70 | 5-52 | 600-1400 | 58 | 2.5-3.5 | 378 | 82 |

| 8/6E-G | 120 | 126-576 | 35-160 | 6-45 | 800-1400 | 60 | 3-4.5 | 378 | 127 |

| 10/8S-GH | 560 | 216-936 | 60-260 | 18-80 | 500-1000 | 65 | 3-7.5 | 533 | 180 |

| 10/8S-G | 560 | 180-1440 | 50-400 | 13-50 | 500-950 | 72 | 2.5-5 | 711 | 178 |

| 12/10G-G | 600 | 360-1440 | 100-400 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 | 220 |

| 12/10G-GH | 1200 | 288-2808 | 80-780 | 16-80 | 350-700 | 73 | 2.0-10.0 | 950 | 210 |

| 14/12G-G | 1200 | 576-3024 | 160-840 | 8-70 | 300-700 | 68 | 2.0-8.0 | 864 | 241 |

| 16/14TU-GH | 1200 | 324-3600 | 90-1000 | 26-70 | 300-500 | 72 | 3.0-6.0 | 1270 | 230 |

| 18/16T-G | 1200 | 720-4320 | 200-1200 | 12-48 | 250-500 | 72 | 3.0-6.0 | 1067 | 254 |

Product Overview

Applications

Mining & Mineral Processing

The slow running speeds of the NAIPU Heavy Duty Slurry Pump,together with the comprehensive choice of abrasion resistant alloys and elastomers,provide unrivalled performance and service life for all abrasive mining and mineral processing applications.

Chemical Process

The interchangeability of alloy and elastomer components in the same pump casing, together with a wide range of mechanical seals.

Sand & Gravel

Designed for easy and simple strip down and re-assembly,the NAIPU PUMP minimises downtime,making it the ideal choice where installed stand by pumps are not available.

Sugar Processing

The premium reliability and service life of the NAIPU pump is specified by many sugar plant engineers worldwide where uninterrupted pump operation during the sugar campaign is a critical requirement.

Flue Gas Desulphurization

The new generation of speciality formulated abrasion and corrosion resistant alloys,together with the very latest elastomer technology.

Oil & Gas Exploration

Over a number of years we have developed the proven design of the NAIPU pump ranges to suit the specific demands of offshore applications,we can now offer the most reliable top side solution to erosion wear.

Naipu Main Slurry Pump Models

| NP-AH | NP-HH | NP-SP | NP-G | NP-AF | NP-L | NP-M |

| 1.5/1B-AH(R) | 1.5/1C-HH | 40PV-SP(R) | 6/4D-G | 3QV-AF | 20A-L | 10/8R-M |

| 2/1.5B-AH(R) | 3/2D-HH | 65QV-SP(R) | 8/6E-G | 4RV-AF | 50B-L(R) | 10/8E-M |

| 3/2C-AH(R) | 4/3E-HH | 100RV-SP(R) | 10/8F-G | 6SV-AF | 75C-L |

|

| 4/3C-AH(R) | 4/3X-HH | 150SV-SP(R) | 12/10G-G | 8SV-AF | 100D-L |

|

| 6/4D-AH(R) | 6/4X-HH | 200SV-SP(R) | 14/12G-G |

| 150E-L |

|

| 6/4E-AH(R) | 6/4F-HH | 250TV-SP | 14/12T-G |

| 300S-L |

|

| 8/6E-AH(R) | 6S-H |

| 16/14G-G |

| 350FF-L |

|

| 8/6R-AH(R) | 6S-HP |

| 16/14TU-GH |

| 450ST-L |

|

| 10/8F-AH(R) | 8/6S-H |

| 18/16G-G |

|

|

|

| 10/8ST-AH(R) | 8/6S-HP |

| 18/16TU-GH |

|

|

|

| 12/10ST-AH(R) | 8/6X-HP |

|

|

|

|

|

| 12/10FF-AH(R) |

|

|

|

|

|

|

| 14/12G-AH(R) |

|

|

|

|

|

|

| 14/12ST-AH(R) |

|

|

|

|

|

|

| 16/14TU-AH(R) |

|

|

|

|

|

|

| 20/18TU-AH(R) |

|

|

|

|

|

|

Naipu Main Pump Parts

Main Slurry Pump Parts : Impeller , Volute Liner , Casing , Throat Bush, Frame Plate Liner Insert , Cover Plate , Frame Plate, Pump Liner Expeller , Expeller Ring ,Stuffing Box , Expeller , Pump Shaft , shaft sleeve, Shaft Spacer, Bearing Assembly , Base, Stuffing Box, Gland Assembly, Bearing Housing , Lantern Ring , pump discharge pipe , flange and so on.

Naipu OEM Pump Parts

There are Rubber Material such as R08 , R12, R26, R33, R38,R55,S03,S12,S31,S21,S42,S51,S52 etc , Wear Resistant Metal Material such as A05,A07,A12, A33, A49, A51,A61 and etc ,Corrosion Resistant Stainless Steel Material such as 201,304, 316, 316L,C55 Duplex Austenitic-Ferritic,Alloy 20,Hastelloy etc, Ceramic lining parts especially suitable for strong abrasion and corrosion mediums,and they can be interchangeable with standard slurry pump parts Ceramic Coated Stainless Steel such as J04,J05,J21,J24,J25,J26,J27,J31 etc.,Resistant Polyurethane like U01,U38, fully meet customers’ request.

We can undertake various OEM Orders for pumps as well as spare parts customized according to drawings or samples.

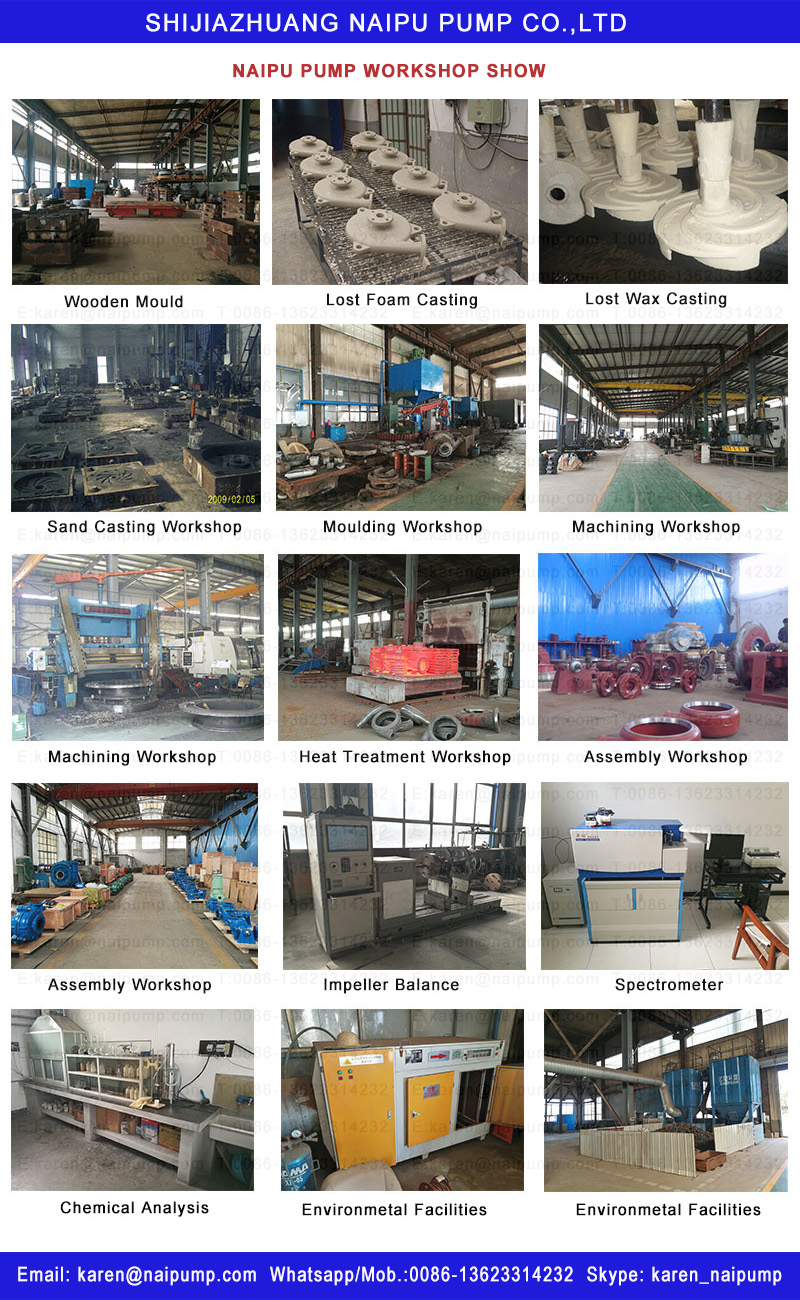

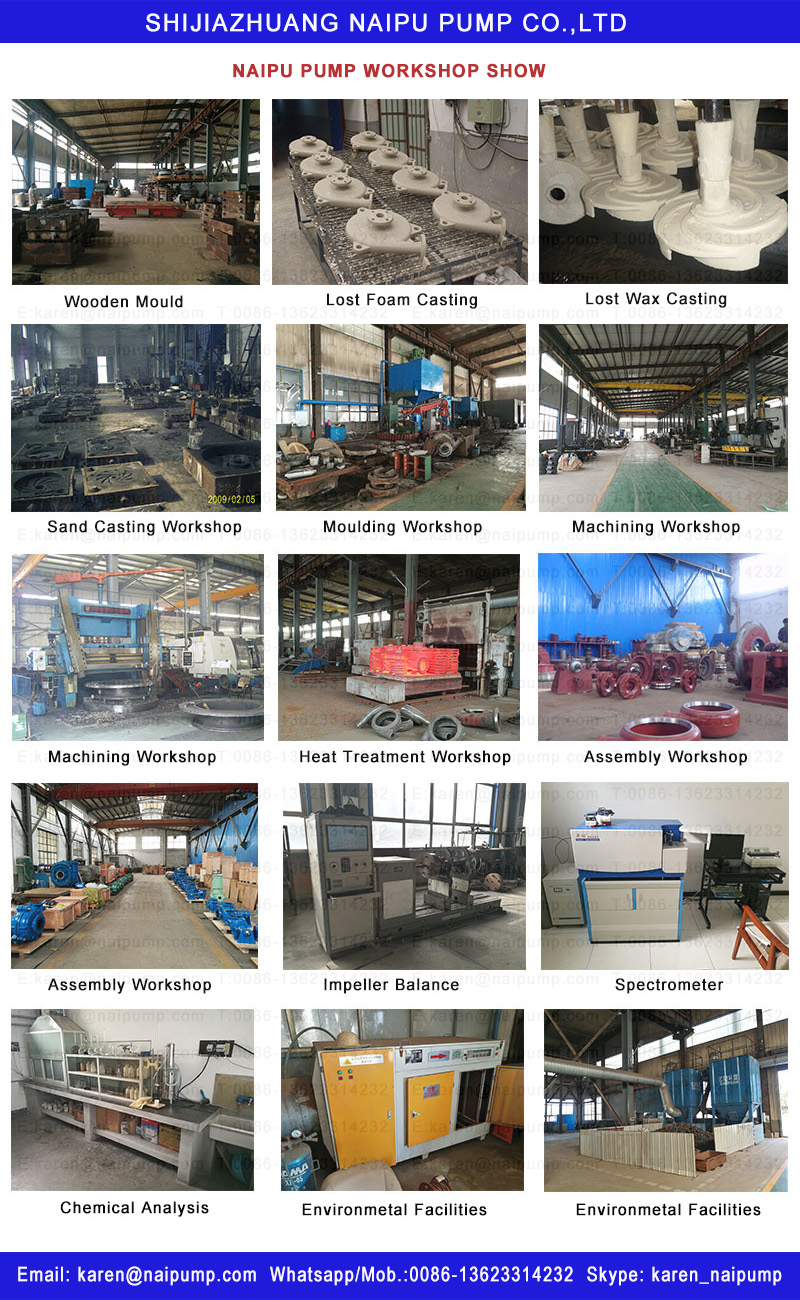

Welcome to visit our Factory !