High Chrome Sand Suction Dredge Slurry Pump

NaiPu is one of professional factory of slurry pump , Sand Gravel Pump , dreding pump and spare parts .

Naipu Slurry Pump Volute Liner can totally interchange with AH HH M L SP AF G Series slury Pump Parts .

We also produce spare parts according the the drawing or sample.

High Chrome Sand Suction Dredge Slurry Pump

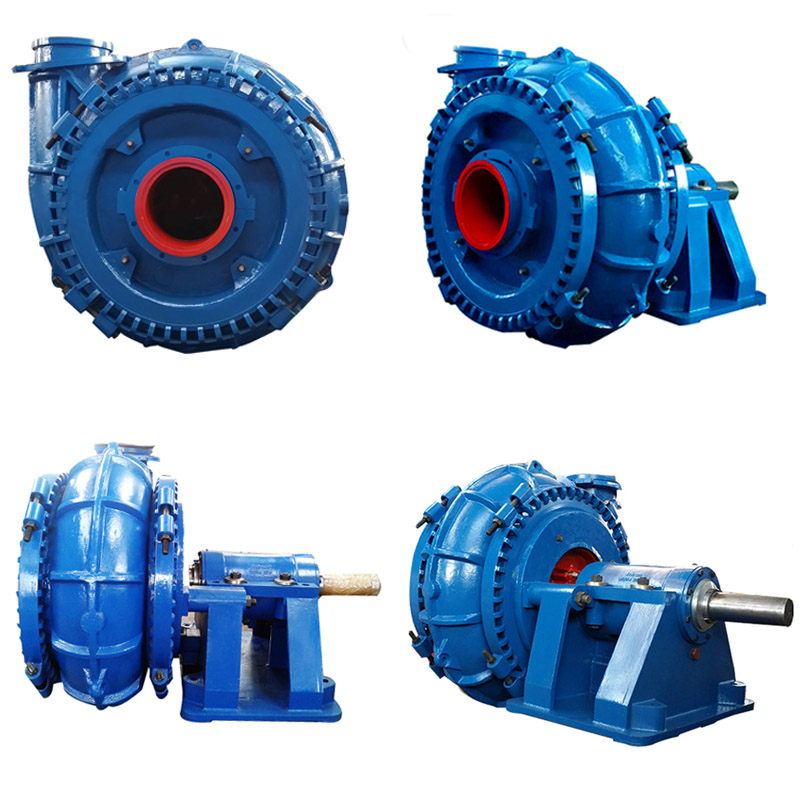

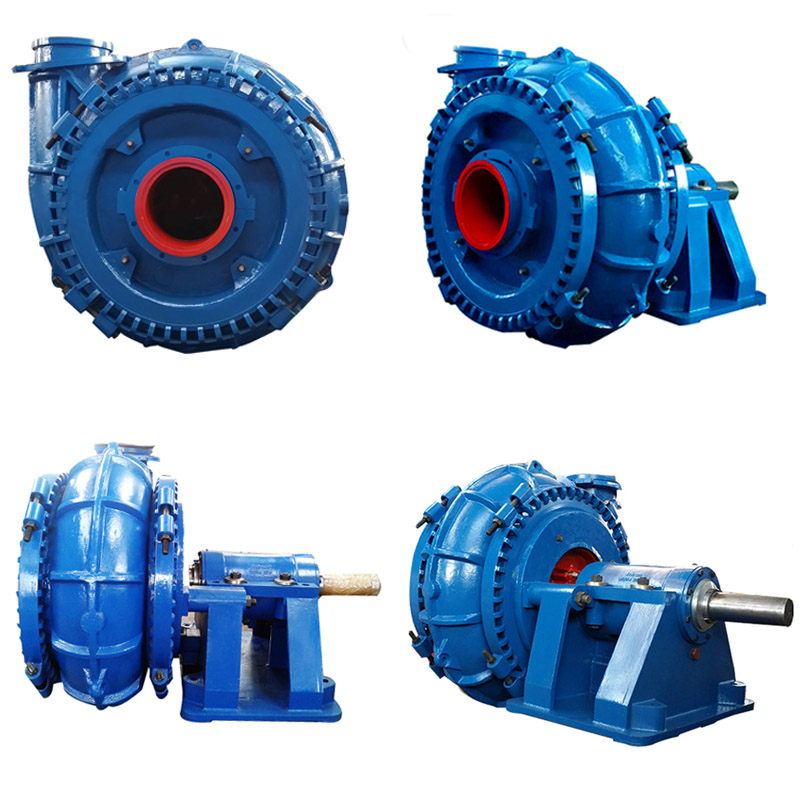

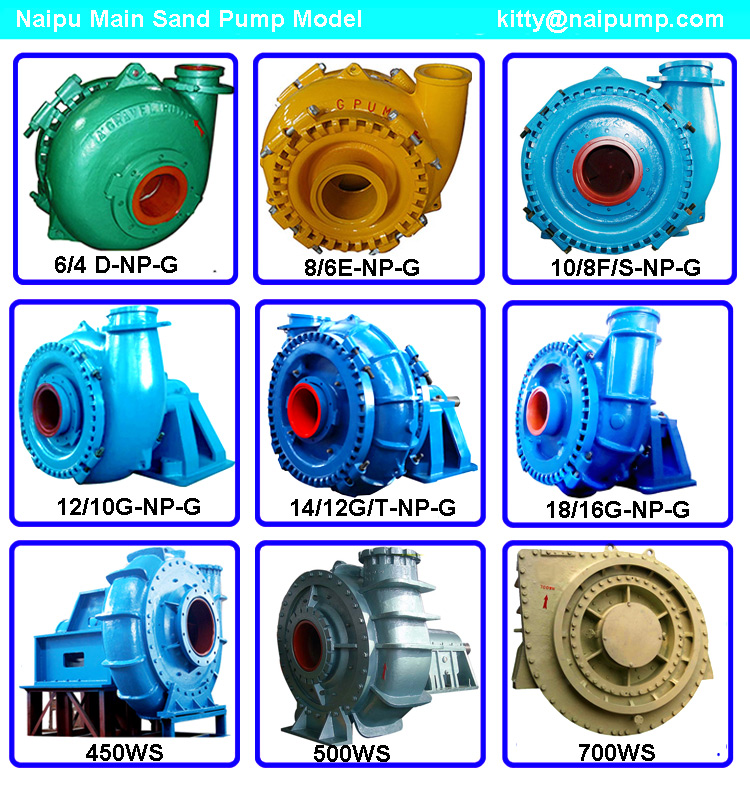

Metal Liner Gravel Pump G TYPE

6/4D-G 8/6E-G 10/8F-G 10/8S-G 12/10F-G 12/10G-G 14/12G-G 10/8S-GH 10/8F-GH 12/10G-GH 12/10F-GH 14/12G-G 14/12T-G 18/16 T-G

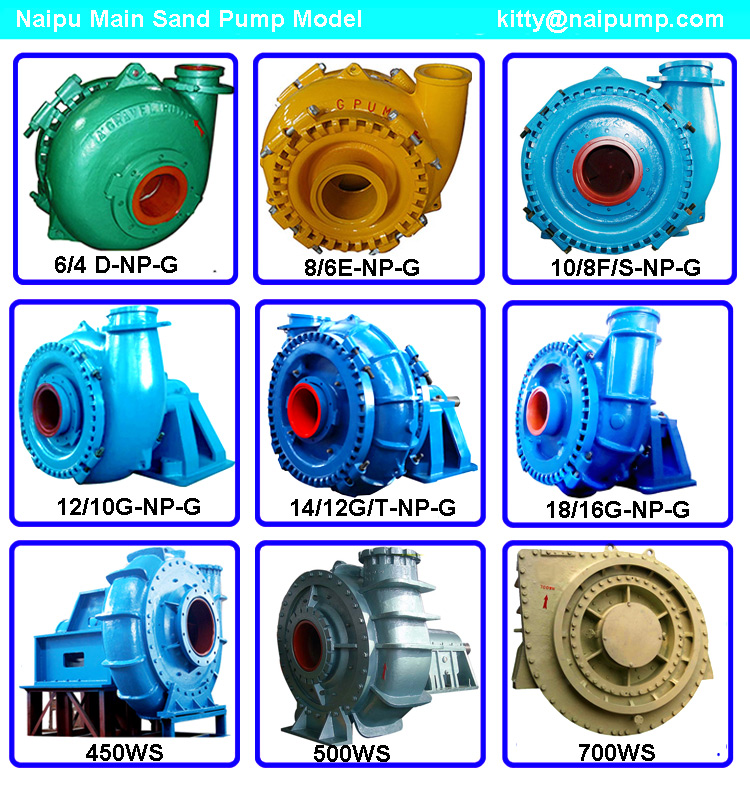

Main Sand Pump

| Pump

Model | Allowable

Max. Power

(kW) | Clear Water Performance | |

| Capacity Q | Head

H(m) | Speed

n(r/min) | Max.Eff.

η% | NPSH

(m) | Impeller

Dia. | Max Solid Passing(mm) |

| m3/h | l/s |

| 6/4D-G | 60 | 36-250 | 10-70 | 5-52 | 600-1400 | 58 | 2.5-3.5 | 378 | 82 |

| 8/6E-G | 120 | 126-576 | 35-160 | 6-45 | 800-1400 | 60 | 3-4.5 | 378 | 127 |

| 10/8S-GH | 560 | 216-936 | 60-260 | 18-80 | 500-1000 | 65 | 3-7.5 | 533 | 180 |

| 10/8S-G | 560 | 180-1440 | 50-400 | 13-50 | 500-950 | 72 | 2.5-5 | 711 | 178 |

| 12/10G-G | 600 | 360-1440 | 100-400 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 | 220 |

| 12/10G-GH | 1200 | 288-2808 | 80-780 | 16-80 | 350-700 | 73 | 2.0-10.0 | 950 | 210 |

| 14/12G-G | 1200 | 576-3024 | 160-840 | 8-70 | 300-700 | 68 | 2.0-8.0 | 864 | 241 |

| 16/14TU-GH | 1200 | 324-3600 | 90-1000 | 26-70 | 300-500 | 72 | 3.0-6.0 | 1270 | 230 |

| 18/16T-G | 1200 | 720-4320 | 200-1200 | 12-48 | 250-500 | 72 | 3.0-6.0 | 1067 | 254 |

Feature and Application

Type ZJS(H) Gravel Pumps are single stage, single casing, centrifugal Horizontal Pump . Sand&Gravel pumps are designed for continuously handling the most difficult higher abrasive slurries which contain too big solids to be pumped by a common pump. They are suitable for delivering slurries in mining, explosive –sludge in metal melting, dredging in dredger and course of rivers, and other fields. Type ZJSH PUMPS are high head ones.

They are suitable for delivering slurries in Mining, explosive-sludge in metal melting, dredging in dredger and course of rivers and other fields.

1. Construction of this pump is of single casing connected by means of clamp bands and wide wet passage.

2. The wet-parts are made of Ni-hard and high chromium abrasion-resistance alloys.

3.The discharge direction of pump can be oriented in any direction of 360°.

4. This type of pump possesses the advantages of easy installation and operation, good performance of NPSH and Abrasion-resistance

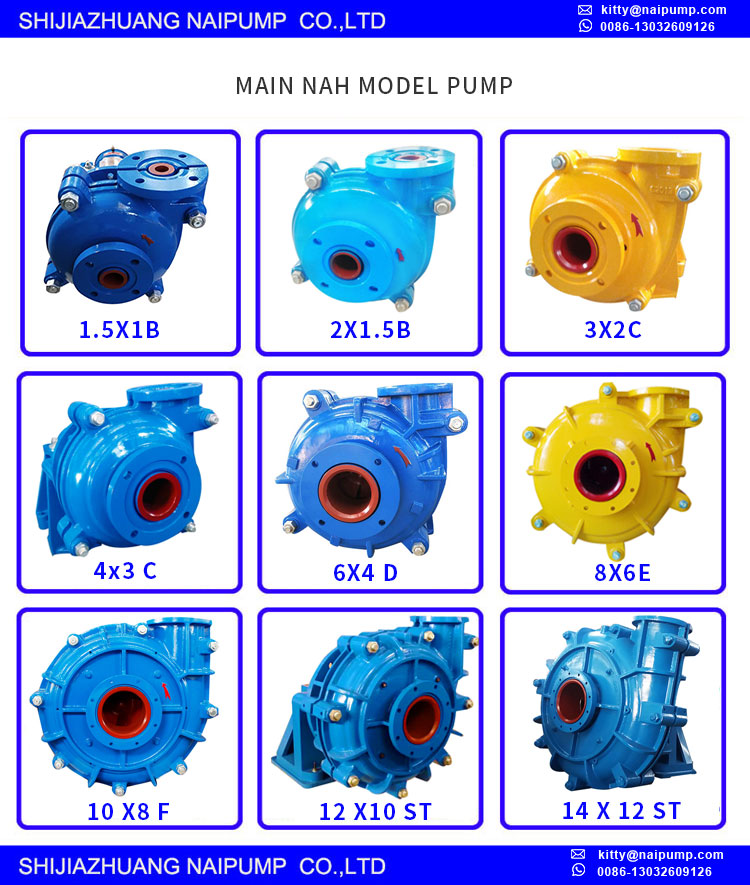

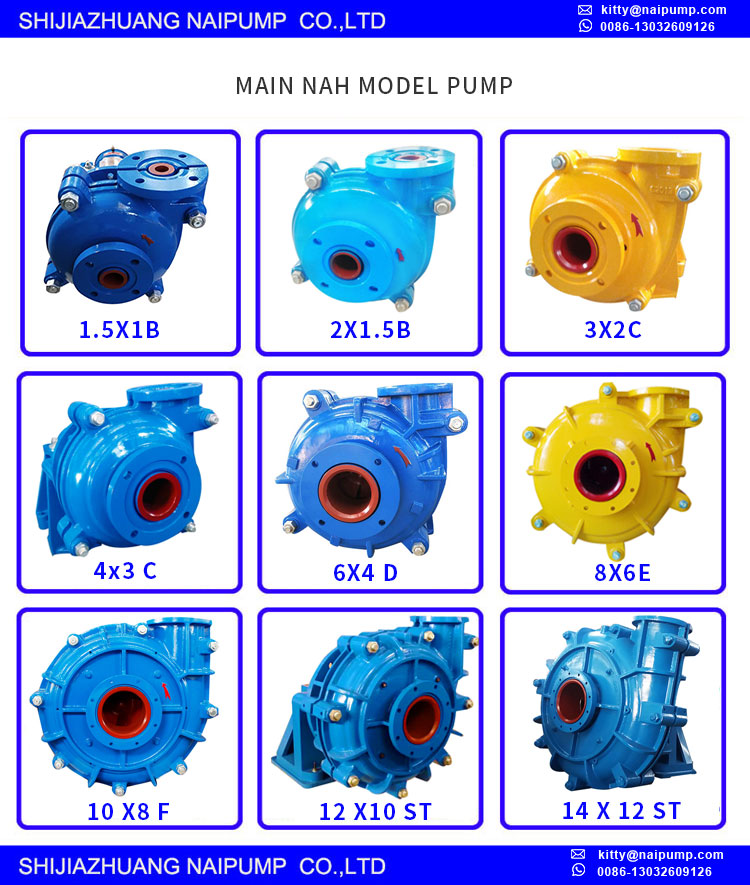

Metal Liner Heavy Duty Slurry Pump AH TYPE

1.5/1B-NAH 2/1.5B-NAH 3/2C-NAH 3/2CC-NAH 4/3C-NAH 4/3CC-NAH 4/3D-NAH 4/3DD-NAH 6/4D-NAH 6/4DD-NAH 6/4E-NAH 6/4EE-NAH 8/6E-NAH 8/6EE-NAH 8/6F-NAH 8/6FF-NAH 8/6R-NAH 10/8ST-NAH 10/8F-NAH 10/8FF-NAH 12/10ST-NAH 12/10G-NAH 12/10F-NAH 12/10FF-NAH 14/12ST-NAH 14/12G-NAH 14/12FF-NAH 14/12F-NAH 16/14TU-NAH 20/18TV-NAH

| Type | Allowable Mating Max. Power(Kw) | Clear Water Performance | Impeller |

| Capacity/Q m³/hr | Head/m | Speed/rpm | Max Efficiency/% | NPSH/m | Nos of Vane | Impeller Diameter/mm |

| 1.5X1-NP-NAH | 15 | 12.6--28.8 | 6--68 | 1200--3800 | 40 | 2--4 | 5 | 152 |

| 2X1.5-NP-NAH | 15 | 32.4--72 | 6--58 | 1200--3200 | 45 | 3.5--8 | 5 | 184 |

| 3X2-NP-NAH | 30 | 39.6--86.4 | 12--64 | 1300--2700 | 55 | 4--6 | 5 | 214 |

| 4X3-NP-NAH | 30 | 86.4--198 | 9--52 | 1000--2200 | 71 | 4--6 | 5 | 245 |

| 6X4-NP-NAH | 60 | 162--360 | 12--56 | 800--1550 | 65 | 5--8 | 5 | 365 |

| 8X6-NP-NAH | 300 | 360--828 | 10--61 | 500--1140 | 72 | 2--9 | 5 | 510 |

| 10X8-NP-NAH | 560 | 612--1368 | 11--61 | 400--850 | 71 | 4--10 | 5 | 686 |

| 12X10-NP-NAH | 560 | 936--1980 | 7--68 | 300--800 | 82 | 6 | 5 | 762 |

| 14X12-NP-NAH | 560 | 1260--2772 | 13--63 | 300--600 | 77 | 3--10 | 5 | 965 |

| 16X14-NP-NAH | 1200 | 1368--3060 | 11--63 | 250--550 | 79 | 4--10 | 5 | 1067 |

| 20X18-NP-NAH | 1200 | 2520--5400 | 13--57 | 200--400 | 85 | 5--10 | 5 | 1370 |

Feature and Application

Horizontal Slurry Pumps are cantilevered, horizontal, Centrifugal Slurry Pump. They are designed for the handing high density slurries in the metallurgical, mining , coal, power, building material and other industrial department etc.

The frame plates liner and impeller for Horizontal Slurry pumps have replaceable wear-resistant metal liners or rubber liners.

The shaft seals may be adoptable of gland seal , expeller seal or Mechanical seal .

The Horizontal Slurry pumps are using for handing strong abrasive, high density slurries and low density, high head slurries in the metallurgical, mining, coal, power, building material and other industrial departments etc.

For example: Coal washery processing, handling with the fine ore and tailings in metal mine, handing combined bottom and fly ash in a thermal power station.

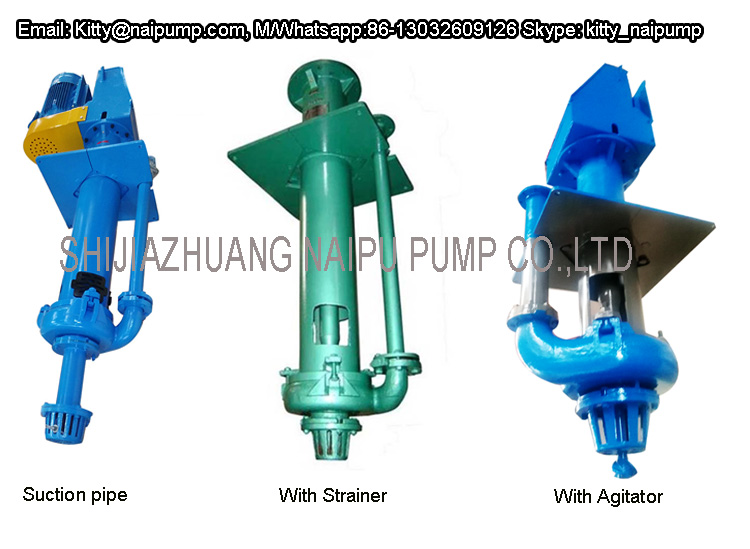

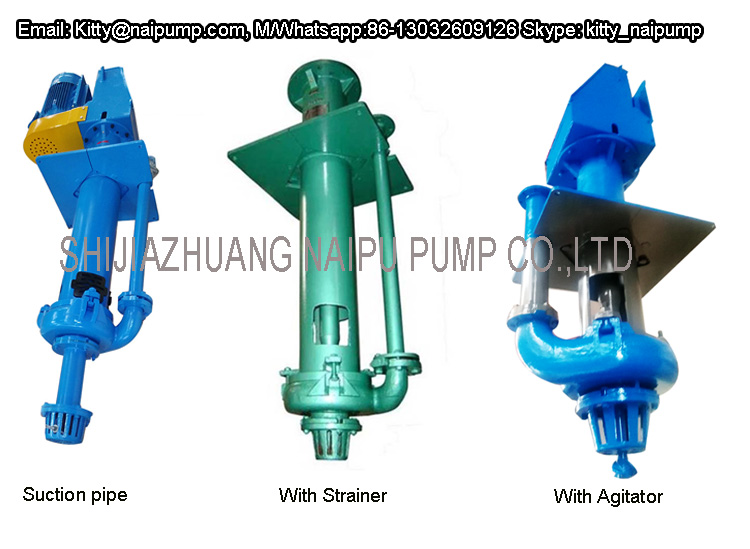

NAIPU-SP Vertical Slurry Sand Sump Pump

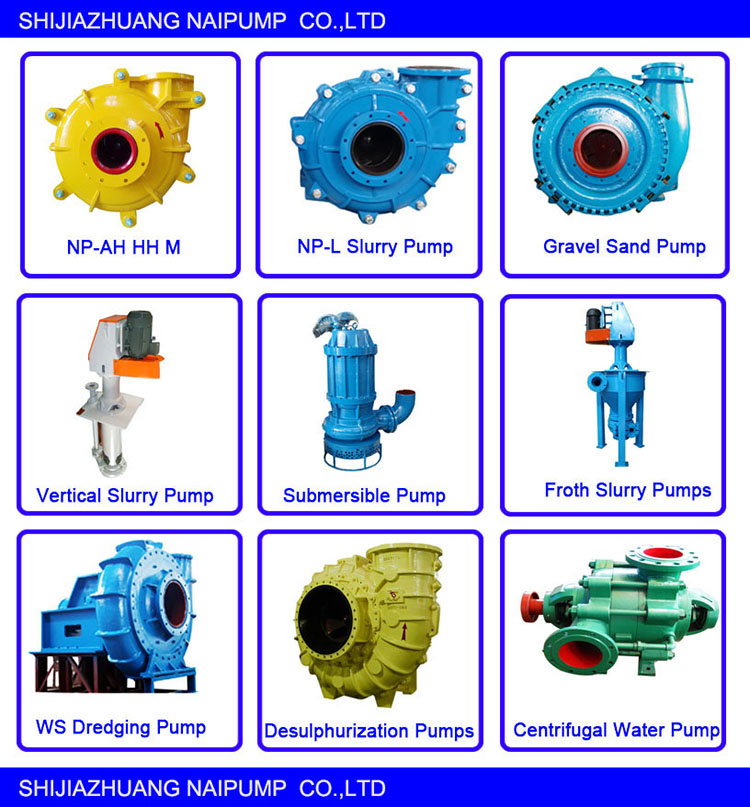

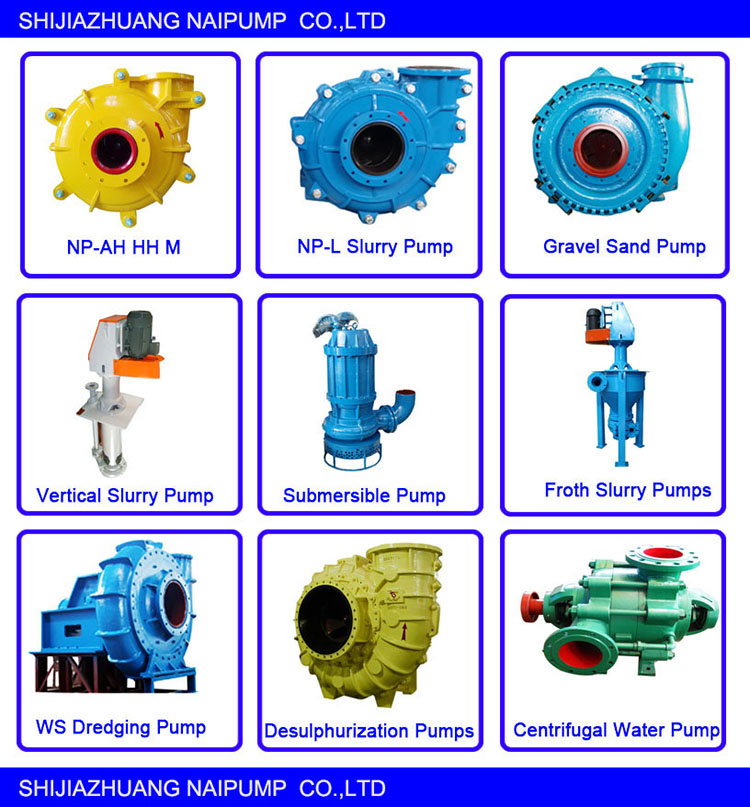

NaiPu Related Pump

NaiPu Main products

1. AH HH M Horizontal Slurry Pump

2. SP Vertical Sump Pump

3. ZJQ Submersible Slurry Pump

4. G Horizontal sand gravel pump

5. ZJQ Submersible sand pump

6. WS Dredging Pump

7. AF Froth Pump

8. TL(R) Desulphurization Pump

8. Clean Water Pump

9. OEM Casting machinery parts

| AH series | L(R) ,M | HH | SP(R) | G | AF Series |

| 1.5/1B-NAH(R) | 20A-L | 1.5/1 C-HH | 40PV-SP(R) | 6/4D-G | 2QV-AF |

| 2/1.5B-NAH(R) | 50B-L(R) | 3/2D-HH | 65QV-SP(R) | 8/6E-G | 3QV-AF |

| 3/2C-NAH(R) | 75C-L | 4/3E-HH | 100RV-SP(R) | 10/8F-G | 6SV-AF |

| 4/3C-NAH(R) | 100 D-L | 4/3X-HH | 150SV-SP(R) | 10/8S-G | 8SV-AF |

| 6/4D-NAH(R) | 150E-L | 6/4F-HH | 200SV-SP | 12/10G-G | 2AHF |

| 6/4E-NAH(R) | 300S-L | 6/4X-HH | 250TV-SP | 14/12G-G | 3AHF |

| 8/6E-NAH(R) | 10/8 R-M | 6S-H | | 14/12T-G | 4AHF |

| 8/6R-NAH(R) | 10/8 E-M | 8/6S-H | | 16/14 G-G | 6AHF |

| 10/8F-NAH(R) | 12/10F-M | 8/6X-H | | 16/14TU-GH | |

| 10/8X-NAH(R) | | 6S-HP | | 16/14H-GH | |

| 12/10ST-NAH(R) | | 8/6S-HP | | 18/16G-G | |

| 14/12ST-NAH(R) | | 8/6X-HP | | 18/16 TU-GH | |

| 16/14TU-NAH(R) | | | | | |

| 20/18G(TU)-NAH(R) | | | | | |

Application

The parts are widely used in Main Applications: Heavy Mining | Mineral Processing | Sand and Gravel |Coal Prep | Cyclone Feeds | Aggregate Processing | Fine Primary Mill Grinding | Chemical Slurry Service | Tailings | Secondary Grinding | Industrial Processing | Pulp And Paper | Food Processing | Cracking Operations | Ash Handling | Pipeline Transport | High Velocity Hydraulic Transport |Food Processing | Explosive Sludge In Metal Smelting | River And Pond Dredging | Heavy Refuse Removal | Larger Particle Or Low NPSHA Applications | Continuous (Snore) Sump Pump Operation | Abrasive Slurries | High Density Slurries | Large Particle Slurries | Sump Drainage | Wash down | Floor Drainage | Mixing | Iron Ore | Cooper | Diamond | Alumina | Coal | Gold | Kaolin | Phosphorite | Steel | Palm | Suger | Chemical | Power | FGD | Frac Sand Blending | Construction | City Sewage | etc.

Pump Spare Parts

Main Slurry Pump Parts : Impeller , Volute Liner , Casing , ThroatBush, Frame Plate Liner Insert , Cover Plate , Frame Plate, Pump Liner Expeller , Expeller Ring ,Stuffing Box , Expeller , Pump Shaft , shaft sleeve, Shaft Spacer, Bearing Assembly , Base, Stuffing Box, Gland Assembly, Bearing Housing , Lantern Ring , pump discharge pipe , flange , and so on.

OEM Sevice

Based on many years of rich experience in slurry pump manufacturing and design, NAIPU can undertake OEM customization for the whole set of pump and various spare parts. The Slurry Pump Spare Parts can be made of various material according to customer’s requirement, Such as : Alloy 20, Hastelloy Alloy , A 61 and so on.

Our company undertakes the design, processing and transformation of various special pump parts. According to the user's requirements, Naipu Factory can manufacture various materials and components to meet the needs of different working conditions. Or in accordance with user requirements on the existing equipment technology transformation, combined with our company's rich hydraulic model, through advanced computer simulation technology, to provide users with a complete and effective solution.

The pump body, impeller, front liner, rear liner, anti-wear ring and other parts made by our company have good results at the site and have excellent performance. They have been recognized by users and established long-term partnerships.

Naipu Workshop

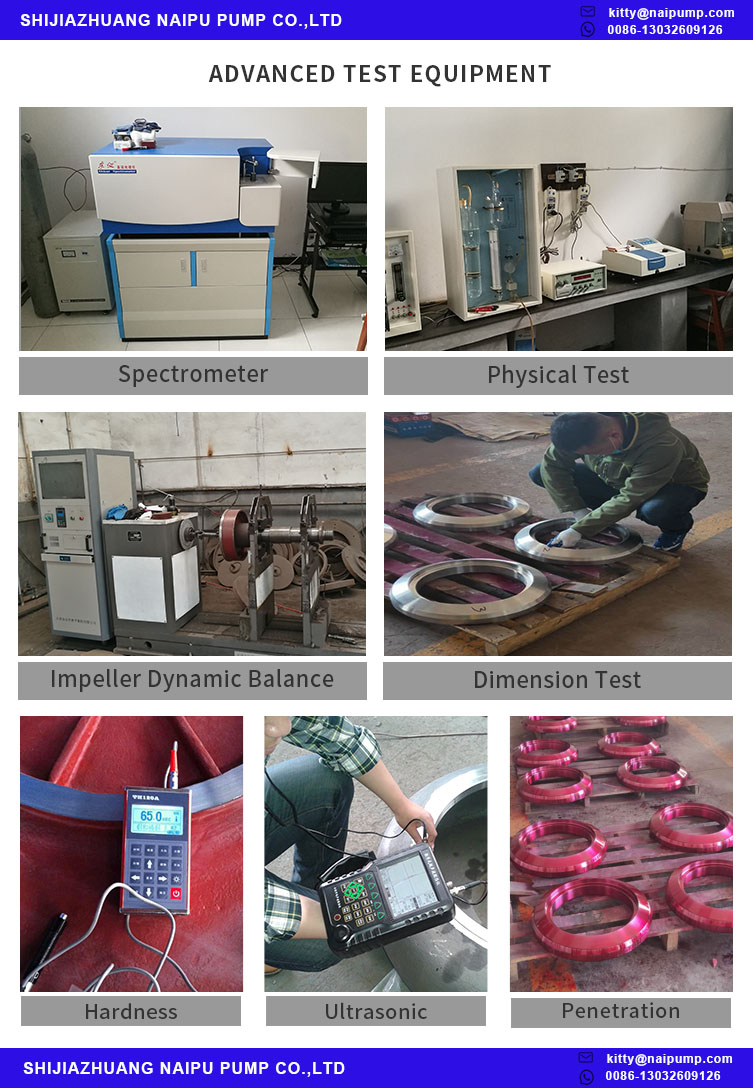

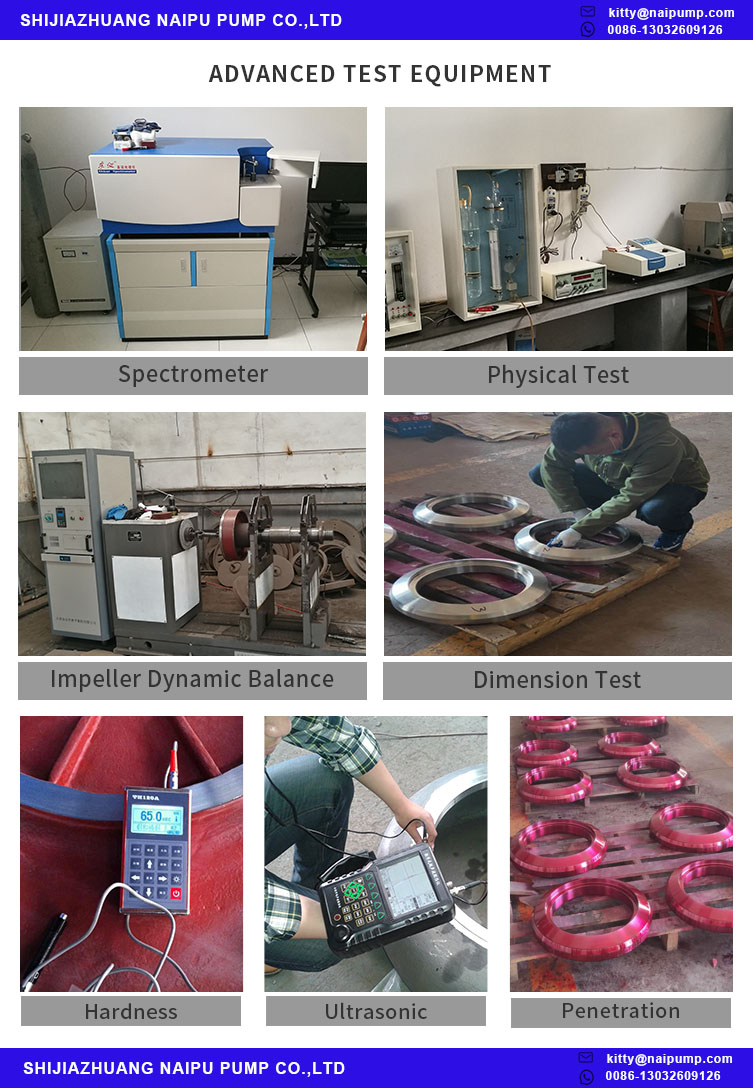

Shijiazhuang NaiPu Pump Co.,Ltd have own Foundry workshop, Machining Workshop, Assembly workshop, and advanced test equipment.

Inspection

All the slurry pump and spare parts will be inspected strictlly before delivery.

Customer Visiting

Contact me