12/10G-G River sand dredger gravel pumps

Coal washing sand gravel pumps/delivering slurries in mining gravel pumps/dredging in dredger pumps/river sand dredger gravel pumps/gravel pumps/mining slurry pumps

Features

1.The G series sand and Gravel Pump is a single-suction Slurry Pump that allows the slurry to be sucked in from only one suction side.Available with one impeller,the single-stage horizontal cantilever pump is widely used in dredging,mining and mineral processing industries.

2.A typical feature of this sand and gravel pump is its one-piece case.Other desiable features include the generous passage and abrasion-resistant wet-end parts made from high chrome.

3.Shaft seal options:packing gland seal,expeller seal and mechanical seal.

4.The discharge outlet has 8 positions at 45 degree intervals that can be selected to meet the installation and application requirements.

Advantages

1.Optimized slurry pump system layout simplifies maintenance operation,ensures long service life,and suit the pump for heavy duty tasks of pumping slurries with large solids.

2.One-piece case and wear-resistant hydraulic parts are easy to replace and repair.

3.Wide flow passage allows a large volume of slurry to pass.The sand and gravel pump is specially designed to handle high-abrasion applications that ordinary pumps can't even attempt.

4.The pump head is fixed to the mounting base by a few bolts.Users can adjust the clearance between the impeller and suction liner from underneath a bearing pedestal.

5.Shaft seal options:packing gland seal,centrifugal seal and mechanical seal.Users can easily replace one type of seal with another in order suit the specific pumping application.

Hydraulic Modeling

Wet-end components are cast of hard metal or polyurethane. They are able to maintain good hydraulic performance even when the Dredging Pump is subject to severe wear.This helps the sand and gravel pump achieve optimal levels of pumping efficiency for an extended period,3-vane impeller improves the pump's ability to pass the slurry.

Shaft Seals

Packing Seal

As one of the most commonly used seals for rotating shafts,the gland seal can come with low-flush or full flush arrangement which uses flushing water to prevent media from escaping the pump housing.This kind of seal is suitable for use in almost all pumping applications.In situations where corrosive solids or high temperature might be encountered, aramid fiber is used as packing material for the gland.To further increase the shaft's resistance to abrasion,a ceramic coated shaft sleeve would be used.

Centrifugal seal-expeller

The combination of impeller and expeller creates the pressure needed to seal against leakage.Together with the gland seal or lip seal which is used as the shut-down seal,this type of seal can handle sealing requirements for applications where full-flush gland seal is impractical due to lack of water on the site,or sealing water is allowed to enter inside the pumping chamber to dilute the slurry.

Mechanical seal

Advances in sealing technology allows us to create a mechanical seal that ensures zero leakage. Catridge type mechanical seal facilitates installation and replacement.Other types of mechanical seal are among options to suit the sand and gravel pump for various pumping applications.We also utilize special ceramic and alloys of high strength and hardness on parts that are subjected to friction.Unique design of and seamless fit between the mechanical seal and seal chamber provides excellent resistance to abrasion and shock that ensures its effectiveness under the toughest conditions.

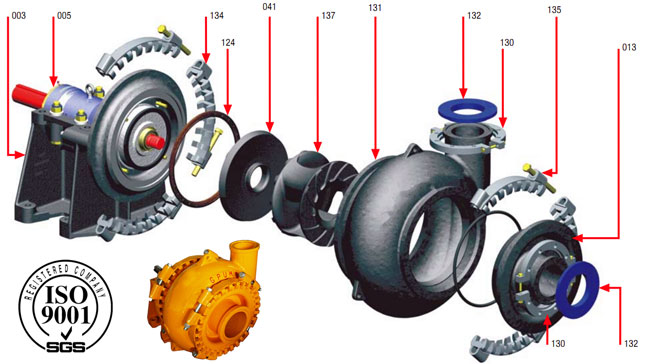

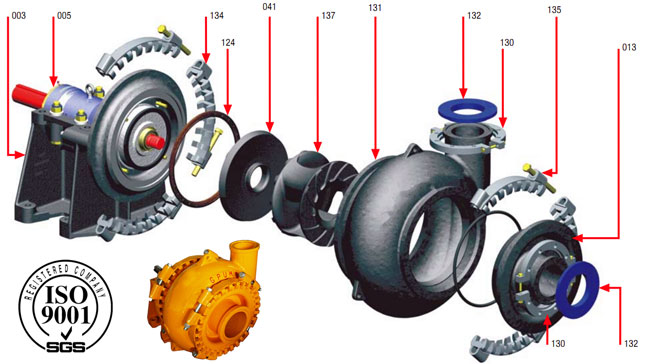

NP-G Construction Drawing--

Main Part Number At The Drawing

003:Base 005: Bearing Assembly 132:Intake Joint Discharge Joint 130:Discharge Flange Intake Flange 013:Cover Plate | 131:Bowl

137:Impeller

041:Back Liner

135:Door Clamp Ring

134: Adapter Plate Clamp Ring

124:Volute Cover Seal |

Materials of Construction

| | VOLUTE | IMPELLERS | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS |

| Standard | High Chrome Alloy | High Chrome Alloy | Cast Iron | Chrome Alloy

or

SG Iron | Chrome Alloy

or

SG Iron | SG Iron | Natural Rubber |

| Options | SG Iron | SG Iron | Mild Steel

Fabricated | SG Iron | SG Iron | EN56C

Ferralium

Hasteloy C

Ceramic

Stellite

Chrome Oxide | Nordel

Neoprene

Viton

Butyl

EPDM |

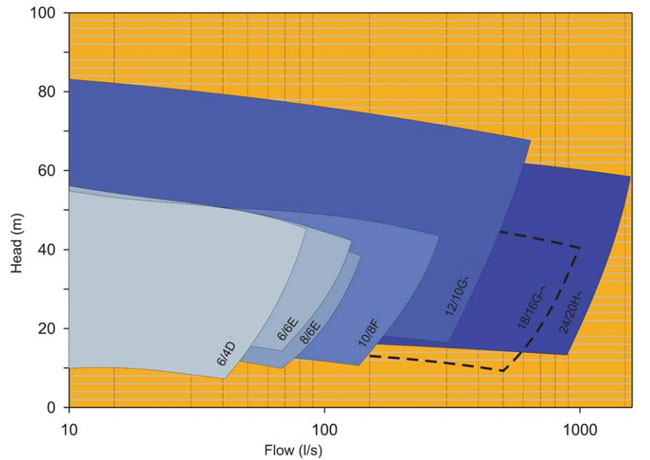

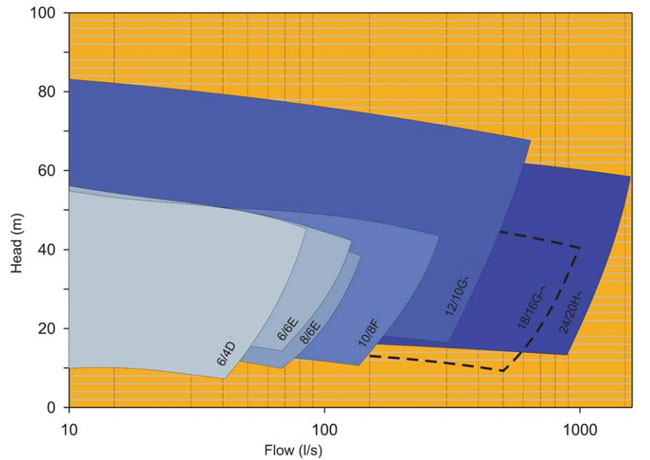

NP-G GRAVEL PUMP SELECTION CHART

NP-G SLURRY PUMP PERFORMANCE PARAMETERS

| Pump Model | Allowable

Max. Power

(kW) | Clear Water Performance | Max Solid Passing (mm) |

| Capacity Q | Head | Speed | Max.Eff. | NPSH | Impeller |

| m3/h | l/s | H(m) | n(r/min) | η% | (m) | Dia. |

| 6/4D-G | 60 | 36-250 | 10-70 | 5-52 | 600-1400 | 58 | 2.5-3.5 | 378 | 82 |

| 8/6E-G | 120 | 126-576 | 35-160 | 6-45 | 800-1400 | 60 | 3-4.5 | 378 | 127 |

| 10/8S-GH | 560 | 216-936 | 60-260 | 18-80 | 500-1000 | 65 | 3-7.5 | 533 | 180 |

| 10/8S-G | 560 | 180-1440 | 50-400 | 13-50 | 500-950 | 72 | 2.5-5 | 711 | 178 |

| 12/10G-G | 600 | 360-1440 | 100-400 | 10-60 | 400-850 | 65 | 1.5-4.5 | 667 | 220 |

| 12/10G-GH | 1200 | 288-2808 | 80-780 | 16-80 | 350-700 | 73 | 2.0-10.0 | 950 | 210 |

| 14/12G-G | 1200 | 576-3024 | 160-840 | 8-70 | 300-700 | 68 | 2.0-8.0 | 864 | 241 |

| 16/14TU-GH | 1200 | 324-3600 | 90-1000 | 26-70 | 300-500 | 72 | 3.0-6.0 | 1270 | 230 |

| 18/16T-G | 1200 | 720-4320 | 200-1200 | 12-48 | 250-500 | 72 | 3.0-6.0 | 1067 | 254 |

Coal washing sand gravel pumps/delivering slurries in mining gravel pumps/dredging in dredger pumps/river sand dredger gravel pumps/gravel pumps/mining slurry pumps

Product Overview

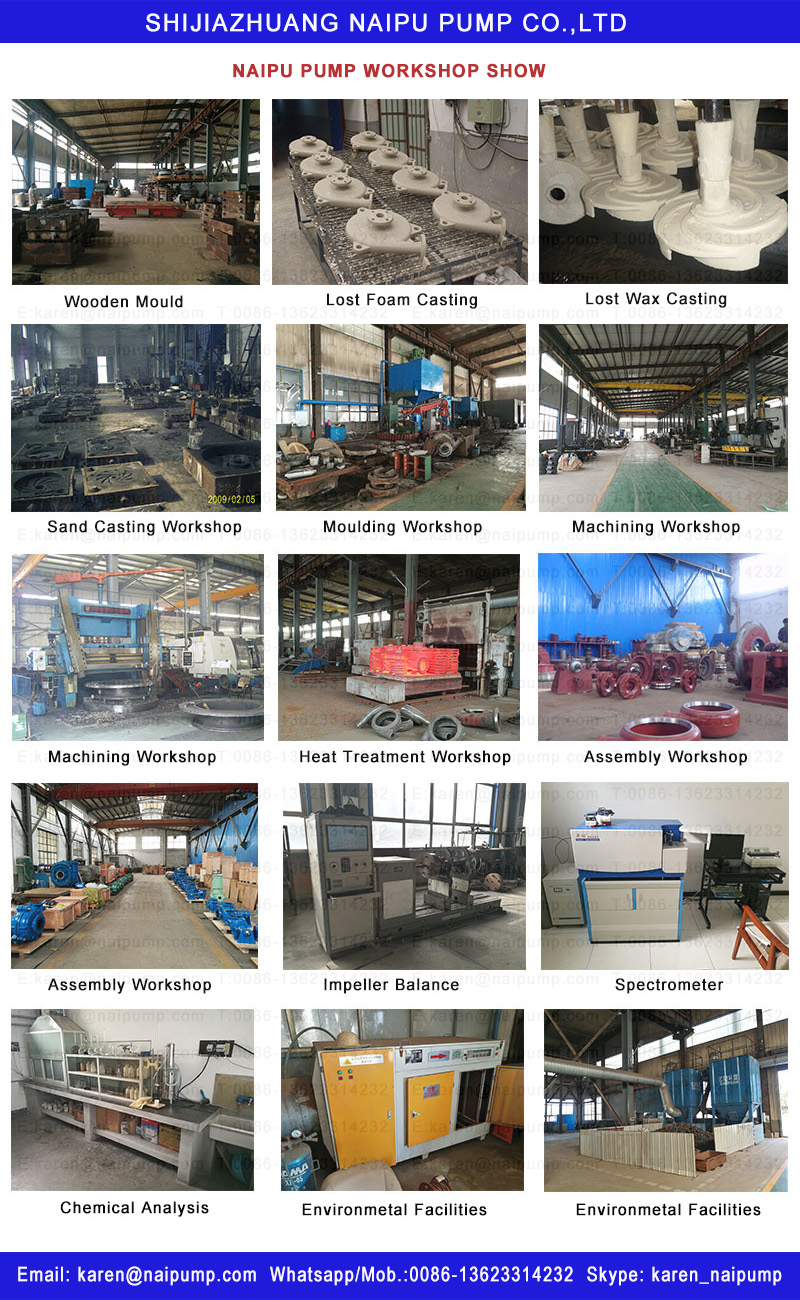

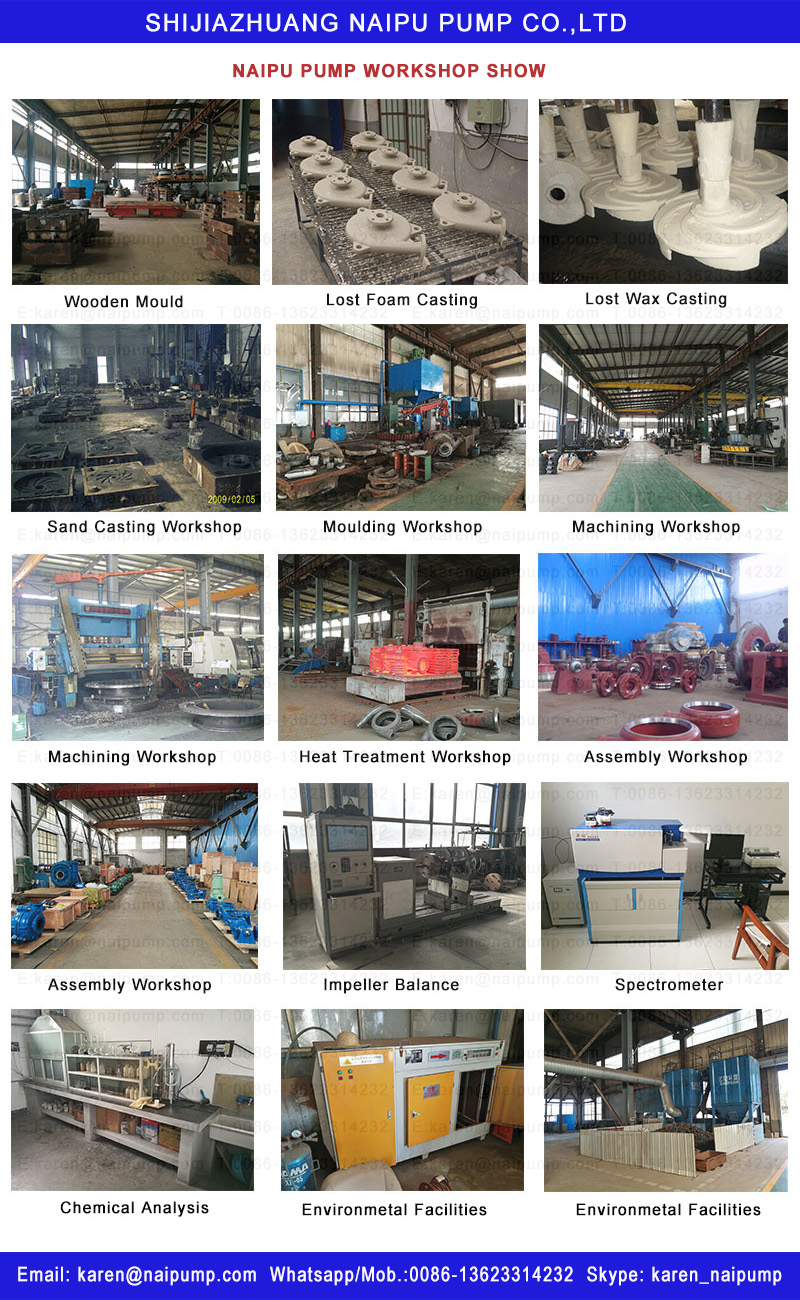

Workshop Photo

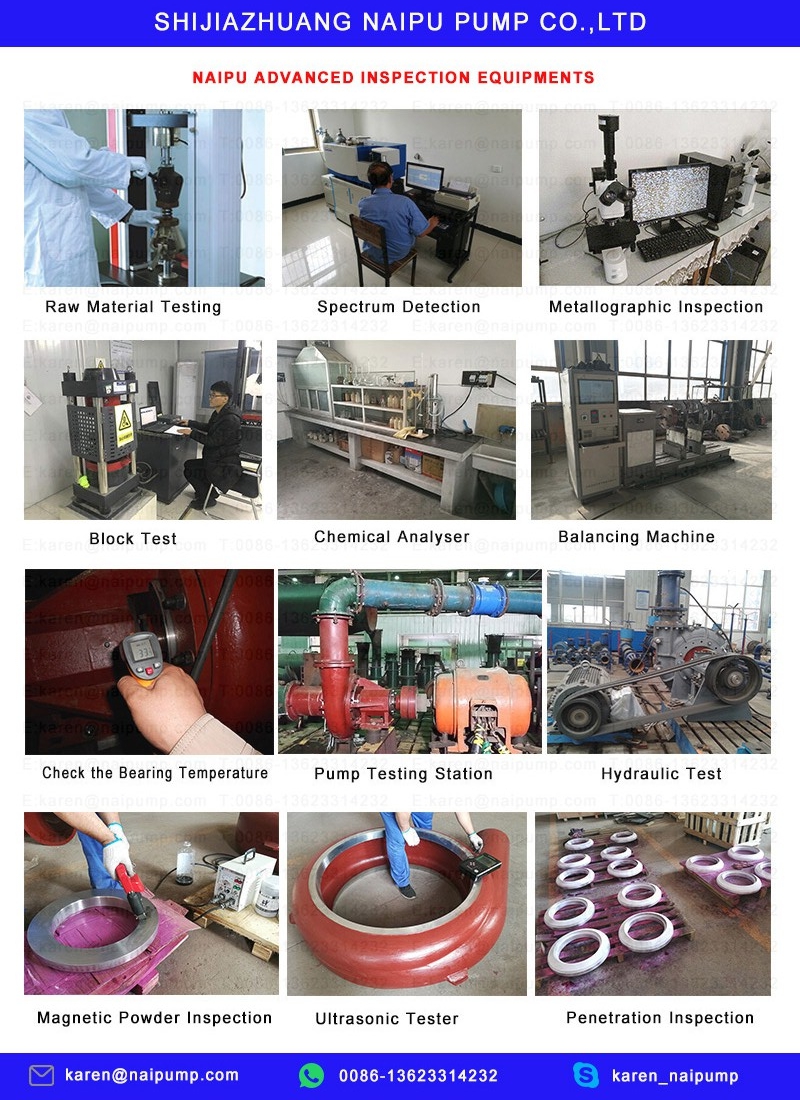

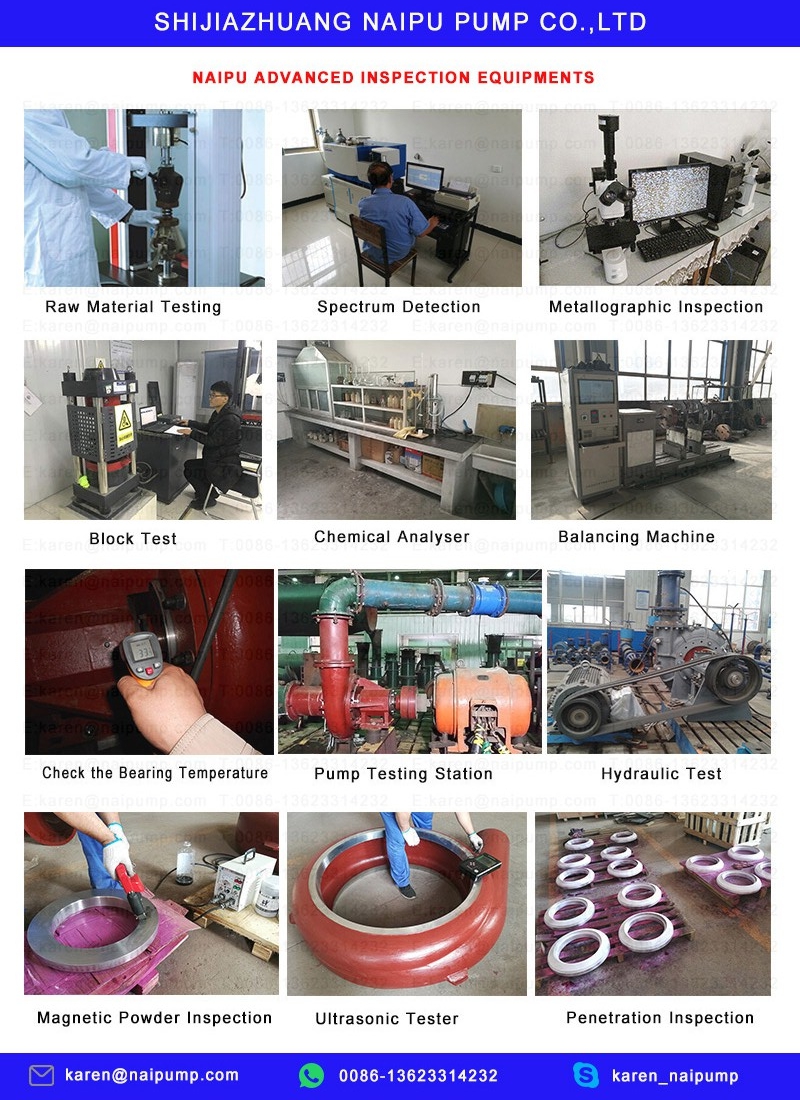

Quality Control:

Application On Site

| Applications |

| Heavy mining | Mineral Processing | Coal Preparation | Cyclone Feeds |

| Chemical Slurry Service | Tailings | Secondary Grinding | Industrial Processing |

| Cracking Operation | Ash Handling | Pipeline Transport | High velocity Hydraulic Transport |

| River and Pond Dredging | Heavy Refuse Removal | Washdown | High density slurries |

| Floor drainage | iron ore | Copper mine | Diamond mine |

| Gold mine | kaolin | phosphorite | steel |

| Chemical | Power | FGD | Frac Sand Blending |

| Aggregate Mining | Pulp and Paper | Food Processing | Fine Primary Mill Grinding |

| Abrasive slurries | Alumina mine | Palm | Construction |

| Food Processing | Explosive in metal smelting | Coal mine | Continuous Sump Pump Operation |

| City Sewage | Sugar | |

|

Contact Details:

Contact: Karen Tan

Skype: karen_naipump

If you have any query,please feel free to contact me freely.