1. APPLICATION of coal mine Slurry Pump

Alumina,Copper mining,Iron ore,Gas oil,Coal ,Electric industry,Phosphate,Bauxite,Gold,Potash, Wolfram,Water sewerage utilities,Sugar,Tobacco,Chemical fertilizer.

Coal mine slurry pumps of ZJ/ZJRSP,SPR,G,L,HH,Series in Shijiazhuang Naipu pump co.,ltd. We can both produce horizontal and Vertical Slurry Pumps with many series, with many years' experience, we also accept OEM Orders.

specifications of coal mine slurry pump

Pump range: 25mm to 450mm (1`` to 18``)

Capacity: 4-5400m3/h

Head: 5-118m

Wet part material commonly is 27Cr white iron alloy or rubber

Other material can be produced as per your specific application

2. Features of coal mine Centrifugal Slurry Pump/centrifugal coal mine slurry pump/mine dewatering pump

1. Double casings design centrifugal slurry pump, wide passage for solids;

2. Bearing Assembly & frame: Both standard & high capacity typies available. A large diameter shaft with a short overhang minimizes deflection and vibration. Heavy duty roller bearing are housed in a removable bearing cartridge. Pump body is fastened with the frame by minimum bolts. Impeller adjustment is provided in a convenient position below the bearing assembly.

3. Impeller & liner material: high chrome white iron, rubber, etc.

4. High efficiency impeller available: up to 86.5% for certain type

5. Interchangeable wet parts material: High chrome alloy metal: PH: 5-12; natural rubber: PH: 4-12;

6. Shaft seal: Packing seal, centrifugal seal, mechanical seal;

7. Discharge branch: 8 positions in each 45°;

8. Driving type: V-belt, flexible coupling, gearbox, hydraulic coupler

3. Material list of Coal mine slurry pumps/centrifugal coal mine slurry pump/mine dewatering pump

| Part Name | Material | Specification | HRC | Application | OEM Code |

| Liners & Impeller | Metal | 23%-30% chrome white iron | ≥56 | Used for higher wear condition with pH between 5 and 12 | A05 |

| 14%-18% chrome white iron | ≥59 | Used for higher wear condition | A07 |

| 27%-29% chrome white iron | 43 | Used for lower pH condition especially for FGD. It also can be used for low-sour condition and desulfuration installation with pH no less than 4 | A49 |

| 33%-37% chrome white iron | | It can transport oxygenated slurry with pH not be less than 1 such as phospor-plaster, nitric acid, vitriol, phosphate etc. | A33 |

| Rubber | | | | R08 |

| | | | R26 |

| | | | R33 |

| | | | R55 |

| Expeller & expeller ring | Metal | 23%-30% chrome white iron | ≥56 | Used for higher wear condition with pH between 5 and 12 | A05 |

| Grey iron | | | G01 |

| Stuffing Box | Metal | 23%-30% chrome white iron | ≥56 | Used for higher wear condition with pH between 5 and 12 | A05 |

| Grey iron | | | G01 |

| Frame/Cover plate, bearing house & base | Metal | Grey iron | | | G01 |

| Ductile iron | | | D21 |

| Shaft | Metal | Carbon steel | | | E05 |

| Shaft sleeve, lantern ring/resctrictor, neck ring, gland bolt | Stainless steel | 4Cr13 | | | C21 |

| 304 SS | | | C22 |

| 316 SS | | | C23 |

| Joint rings & seals | Rubber | Butyl | | | S21 |

| EPDM rubber | | | S01 |

| Nitrile | | | S10 |

| Hypalon | | | S31 |

| Neoprene | | | S44/S42 |

| Viton | | | S50 |

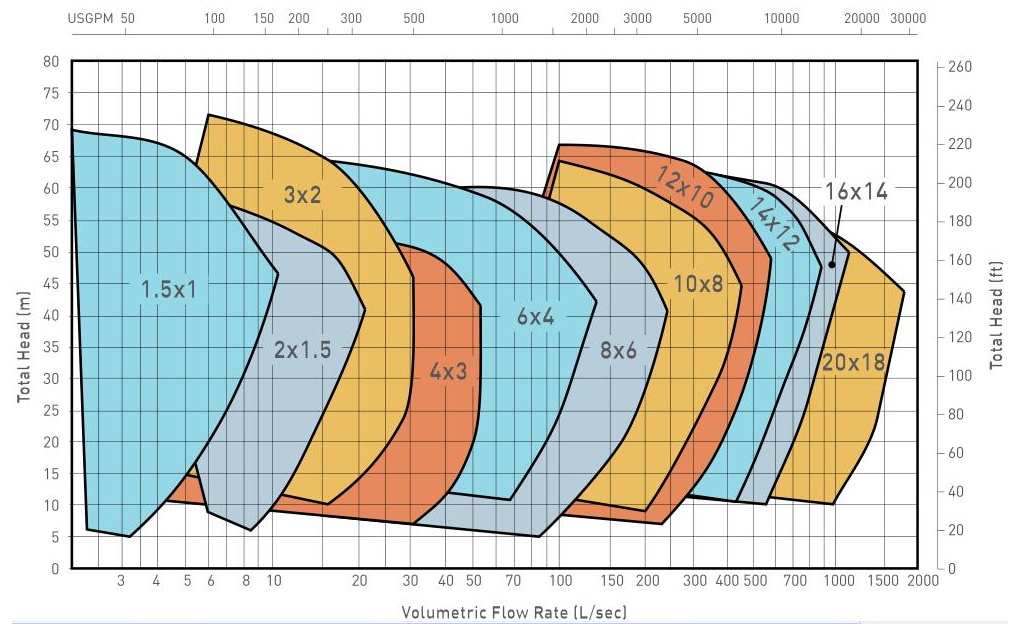

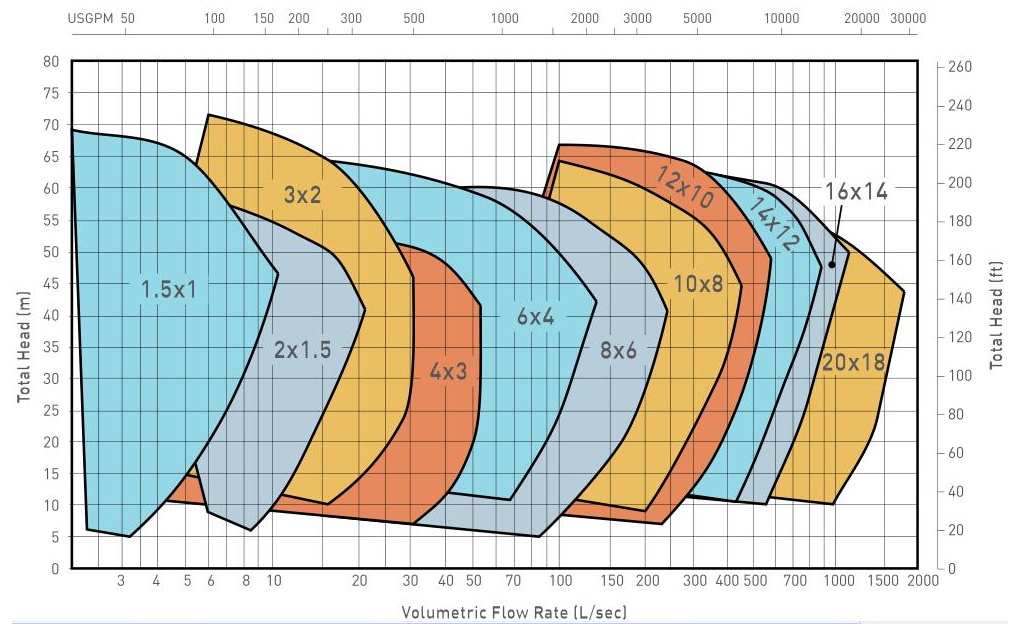

4. Performance curves for Coal mine slurry pump/centrifugal coal mine slurry pump/mine dewatering slurry pump

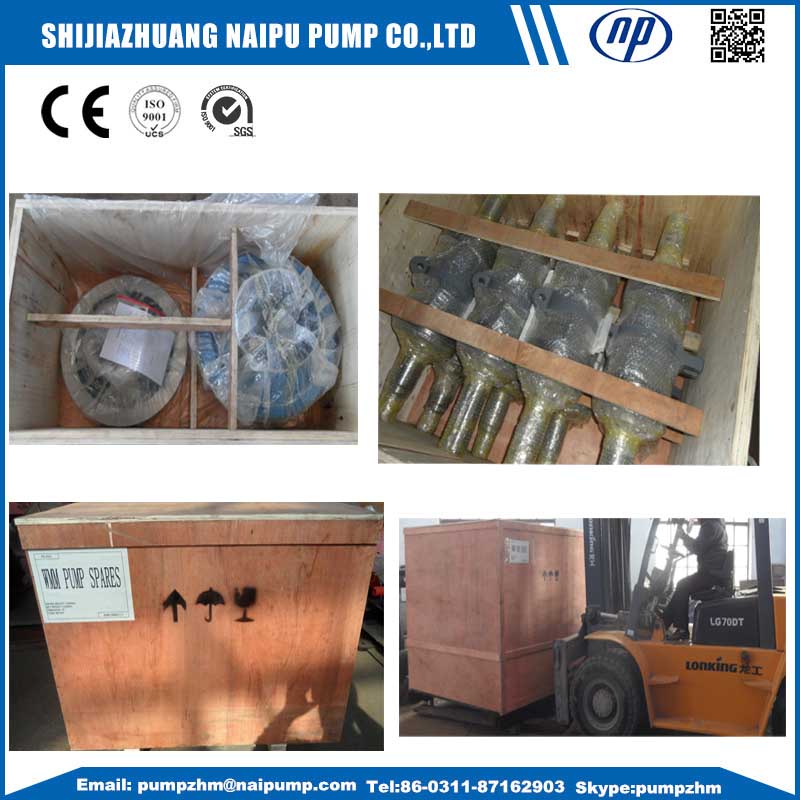

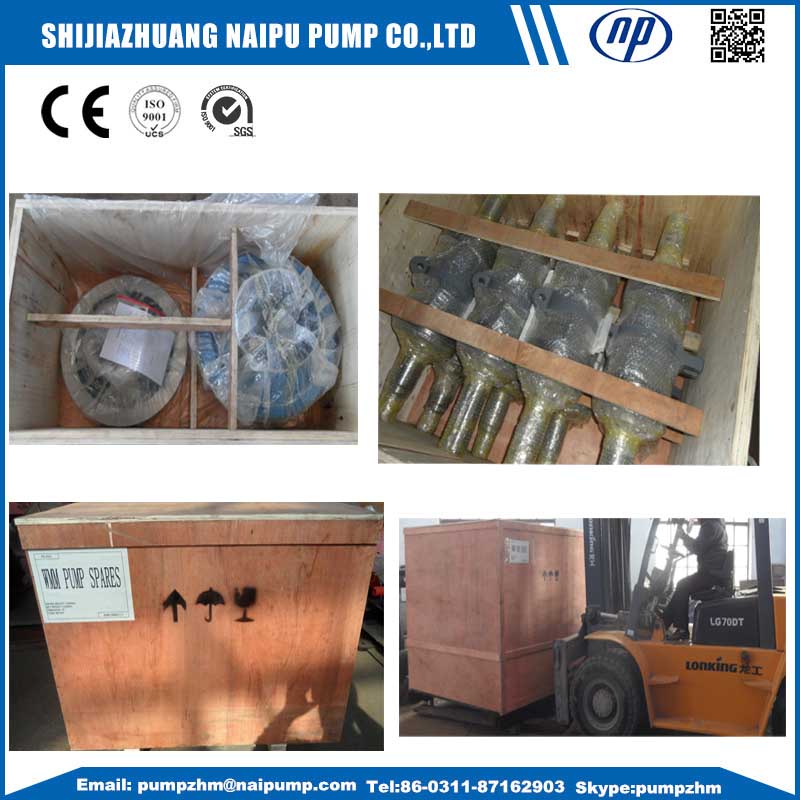

5. Our factory show

6. About Shijiazhuang Naipu Pump Co.,ltd

Naipu believes that after you purchase a product from us our WORK BEGINS. We carry a comprehensive range of spare parts to fully support our range of products. Our commitment to our customers is to offer service and support on a 24/7 Basis.

Our team of technicians are pump experts and we offer our clients quality service for all their pumps and pumping systems. Naipu's technical team have the capacity and skills to cost effectively diagnosis, repair or carryout full equipment and component rebuilds. We have an emergency 24/7 service facility for both in-shop repairs and service as well as field service.

In addition, we can build, custom design and install pumping systems to meet your specific applications or special requirements.

Naipu works to ISO9001: quality management system.

6. centrifugal coal mine slurry pump/mine dewatering slurry pump pictures