10/8 ST-AH Heavy duty slurry pumps

Horizontal Slurry Pumps/Cantilevered centrifugal slurry pumps/handling highly abrasive slurries/metallurgical slurry pumps/coal mine plant processing pumps/wear-resistant metal liners slurry pumps/wear resistant rubber liners slurry pumps/centrifugal slurry pumps

The NP-AH pumps are cantilevered ,horizontal,centrifugal slurry pumps. The frame plates of the pumps have replaceable wear-resistant metal liners or rubber liners.The impellers are made of wear-resistant metal or rubber.The shaft seals for the pumps may be adoptable of gland seal or expeller seal.The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.

Typical Applications--- Minerals Flotation Processing Electric Factory Coal Preparation Coal Washing Chemical Medium Processing Effluent Handling Sand And Gravel Handling

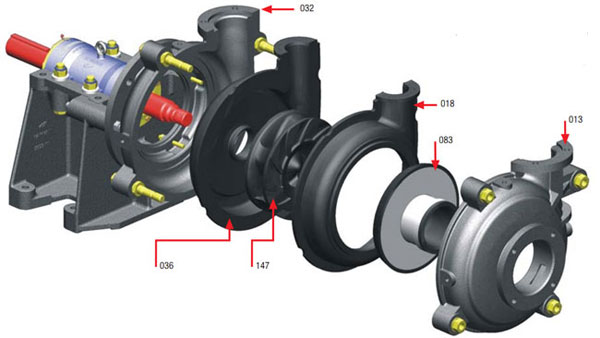

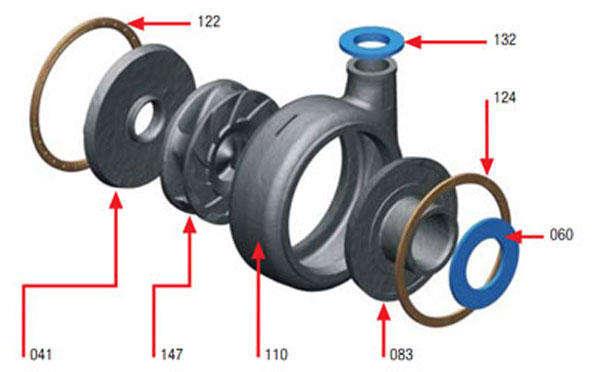

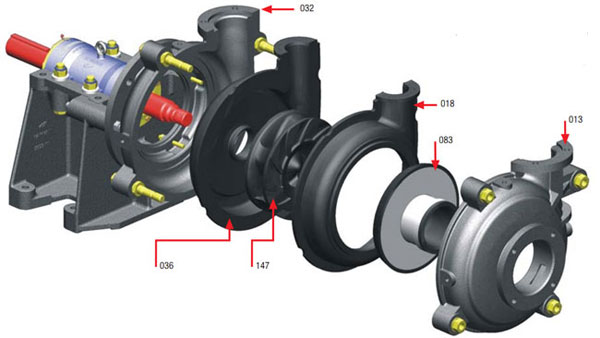

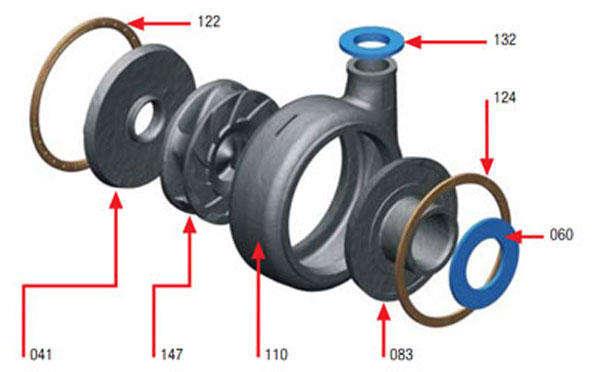

Construction Drawing

Elastomer parts

Metal Lined

Main Part Number At The Drawing

Materials of Construction

| NP-AH Material Construction |

| | LINERS | IMPELLERS | CASING | BASE | EXPELLER | EXPELLER RING | SHAFT SLEEVE | SEALS |

| Standard | Chrome Alloy Natural rubber | Chrome Alloy Natural Rubber | SG Iron | SG Iron | Chrome alloy or SG Iron | Chrome Alloy or SG Iron | SG Iron | Rubber And Nitrile |

| Options | Ferralium Hastelloy C 316SS W151 Polyurethane Neoprene Butyl Nitrile EPDM Hypalon | Ferralium Haselloy C 316SS W151 Polyurethane Neoprene Butyl Nitrile Hypalon | SG Iron Various Grades | MS Fabricated Cast Iron | Ni Resistant Ferralium Hastelloy C Polyurethane 316SS W151 | Ni Resistant Ferralium Hastelloy C 316SS Rubber W151 Polyurethane Neoprene Butyl Nitrile | EN56C Ferralium Hastelloy C Titanium 316SS 304SS | Ceramic Stellite Chrome Oxide Nordel Neoprene Viton |

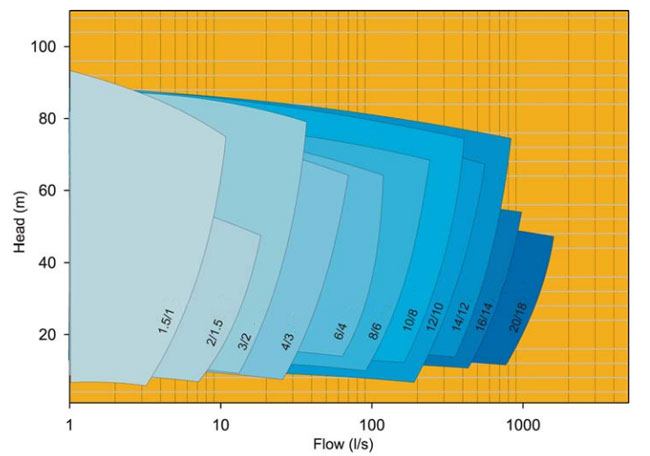

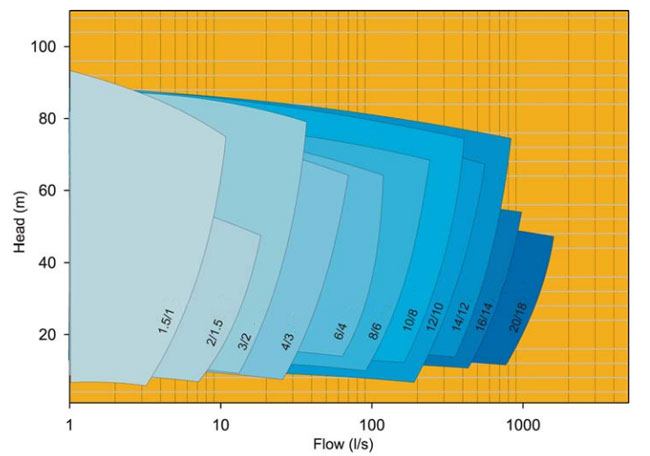

NP-AH(R) PUMP SELECTION CHART

NP-Ah Slurry Pump PERFORMANCE PARAMETERS

| Type | Allowable Mating Max. Power(Kw) | | Clear Water Performance | Impeller |

| Material | Capacity/Q m³/hr | Head/m | Speed | Max Eff% | NPSH/m | Nos of Vane | Impeller Diameter/ |

| rpm | mm |

| 1.5/1-NP-AH | 15 | M | 12.6--28.8 | 6--68 | 1200--3800 | 40 | 2--4 | 5 | 152 |

| R | 10.8-25.2 | 7-52 | 1400-3400 | 35 | 3 |

| 2X1.5-NP-AH | 15 | M | 32.4--72 | 6--58 | 1200--3200 | 45 | 3.5--8 | 5 | 184 |

| R | 25.2-54 | 5.5-41 | 1000-2600 | 50 | 2.5-5 | 178 |

| 3X2-NP-AH | 30 | M | 39.6--86.4 | 12--64 | 1300--2700 | 55 | 4--6 | 5 | 214 |

| R | 36-75.6 | 13-39 | 1300-2100 | 55 | 2--4 | 213 |

| 4X3-NP-AH | 30 | M | 86.4--198 | 9--52 | 1000--2200 | 71 | 4--6 | 5 | 245 |

| R | 79.2-180 | 5-34.5 | 800-1800 | 59 | 3--5 |

| 6X4-NP-AH | 60 | M | 162--360 | 12--56 | 800--1550 | 65 | 5--8 | 5 | 365 |

| R | 144-324 | 12-45 | 800-1350 | 65 | 3--5 |

| 8X6-NP-AH | 300 | M | 360--828 | 10--61 | 500--1140 | 72 | 2--9 | 5 | 510 |

| R | 324-720 | 7-49 | 400-1000 | 65 | 5--10 |

| 10X8-NP-AH | 560 | M | 612--1368 | 11--61 | 400--850 | 71 | 4--10 | 5 | 686 |

| R | 540-1188 | 12-50 | 400-750 | 75 | 4--12 |

| 12X10-NP-AH | 560 | M | 936--1980 | 7--68 | 300--800 | 82 | 6 | 5 | 762 |

| R | 720-1620 | 7-45 | 300-650 | 80 | 2.5-7.5 |

| 14X12-NP-AH | 560 | M | 1260--2772 | 13--63 | 300--600 | 77 | 3--10 | 5 | 965 |

| R | 1152-2520 | 13-44 | 300-500 | 79 | 3--8 |

| 16X14-NP-AH | 1200 | M | 1368--3060 | 11--63 | 250--550 | 79 | 4--10 | 5 | 1067 |

| 20X18-NP-AH | 1200 | M | 2520--5400 | 13--57 | 200--400 | 85 | 5--10 | 5 | 1370 |

Horizontal slurry pumps/Cantilevered centrifugal slurry pumps/handling highly abrasive slurries/metallurgical slurry pumps/coal mine plant processing pumps/wear-resistant metal liners slurry pumps/wear resistant rubber liners

| Metal Lined Pump Material |

| No | Part Name | Materials | No | Parts Name | Materials |

| 1 | Liner | Cr26 High Chrome Alloy | 1 | Frame Plate | QT500-7 |

| 2 | Frame Plate | QT500-7 | 2 | Expeller Ring | Cr26 high chrome alloy |

| 3 | Frame Plate Liner Insert | Cr26 High Chrome Alloy | 3 | Gland Assembly | HT200 |

| 4 | Cover Plate | QT500-7 | 4 | Shaft Sleeve | 420 Stainless Steel |

| 5 | Throat Bush | Cr26 High Chrome Alloy | 5 | Expeller | Cr26 High Chrome Alloy |

| 6 | Impeller | Cr26 High Chrome Alloy | 6 | Frame Plate Liner | Rubber |

| 7 | Expeller Ring | Cr26 High Chrome Alloy | 7 | Impeller | Rubber |

| 8 | Shaft Sleeve | 420 Stainless Steel | 8 | Cover Plate Liner | Rubber |

| 9 | Expeller | Cr26 High Chrome Alloy | 9 | Cover Plate | QT500-7 |

| 10 | Bearing Assembly | SKF /Timken (standard) | | |

|

Our Services

1.OEM service is available.

2.Fast producing time.

3.Best quality with competitive price.

4.Reply promptly in 24 hours.

FAQ:

Q1. Are you a manufacturer factory?

Yes,we are the direct manufacture factory,and have more than 10 years' experience in this area.

Q2.Do you have stock products to sell?

Some we have in stock ,but the others not. Since we always produce these products according to customers requirements.

Q3.What advantages do you have?

A: We are direct manufacturer and the price is competitive.

B: Our engineer are very experieced in this area, and we can do OEM service to you.

C:We are factory, and we can arrange production schedule,so as to punctual delivery.

Product Overview:

Naipu Main Pump Types

Application

| Applications |

| Heavy mining | Mineral Processing | Coal Preparation | Cyclone Feeds |

| Chemical Slurry Service | Tailings | Secondary Grinding | Industrial Processing |

| Cracking Operation | Ash Handling | Pipeline Transport | High velocity Hydraulic Transport |

| River and Pond Dredging | Heavy Refuse Removal | Washdown | High density slurries |

| Floor drainage | iron ore | Copper mine | Diamond mine |

| Gold mine | kaolin | phosphorite | steel |

| Chemical | Power | FGD | Frac Sand Blending |

| Aggregate Mining | Pulp and Paper | Food Processing | Fine Primary Mill Grinding |

| Abrasive slurries | Alumina mine | Palm | Construction |

| Food Processing | Explosive in metal smelting | Coal mine | Continuous Sump Pump Operation |

| City Sewage | Sugar | |

|

Contact US:

Shijiazhuang Naipu Pump Co.,Ltd

Add:No.368 Xinshi North Road,Shijiazhuang Hi-Tech Industry Development Zone Hebei,China 050091

Contact Person:Karen Tan

Skype: karen_naipump

If any query,please don't hesitate to contact us.