AF Double Casing Froth Pumps

Rubber Lined Froth Pump/foam pumps/metal lined froth pumps/handling frothy pulp/double casings froth pumps/hopper-tank froth pumps/coal flotation circuits foam pumps.

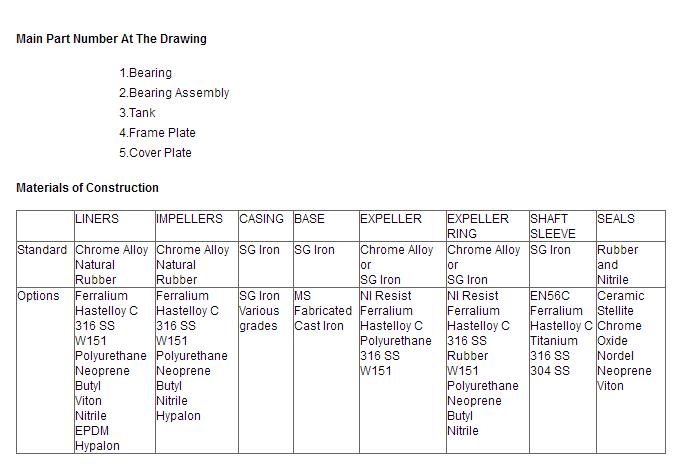

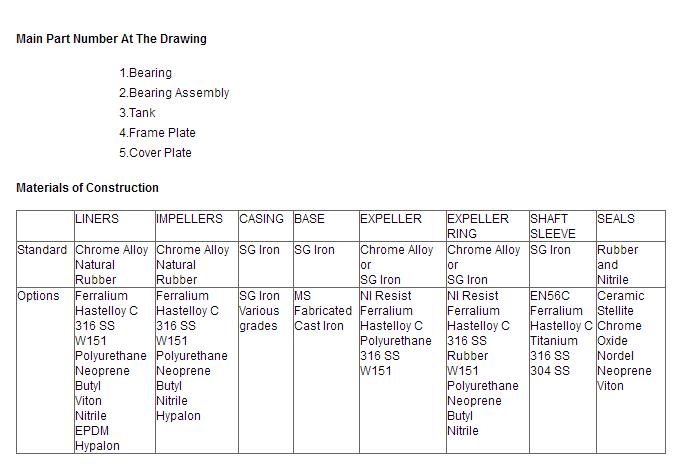

The construction of pump head is double casings Slurry Pump.All wet-ends can be supplied in Ni-hard,high chrome alloy iron and pressure-moulded natural or synthetic rubber.The hopper-tank is fabricated with steel plate.Its inner wall of the tank can be covered with liner according to different medium pumped.The discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications.The advantages of the pump are of excellent performance,easy assembly & disassembly,high and etc.

The froth pump is a efficiency pump are suitable for handling solid-liquid mixture,special for delivering frothy pulpgenerated in flotation machines in metalligerous and coal flotation circuits.

The basic principle of the pump operation is to de-aerate or partially de-aerate the froth before it enters pumping.Its handling capacity of the pump is much higher than that of other types of slurry pump without shaft seal and sealing water.The froth pump is a perfect pump for handling frothy pulp indeed.

Features:

1.Submersed in the slurries,the AF series froth pump is typically used to convey abrasive or corrosive frothy slurries.

2.A typical feature of this vertical Centrifugal Slurry Pump is the double-casing design which allows the case to be split open along its centerline.Wet-end parts are replaceable and made of abrasion-resistant high-chrome.Depending on your specific pumping task,we can rubber and polyurethane to construct the internal pump liner and impeller.

3.The impeller vanes and hopper are specially made to remove any foam produced during pumping operation.

4.Eliminate the need for any shaft seal and sealing water.

5.Parts submerged in the slurry can be made of metal or rubber.

Advantages

1.Simple pump system layout allows easy installation

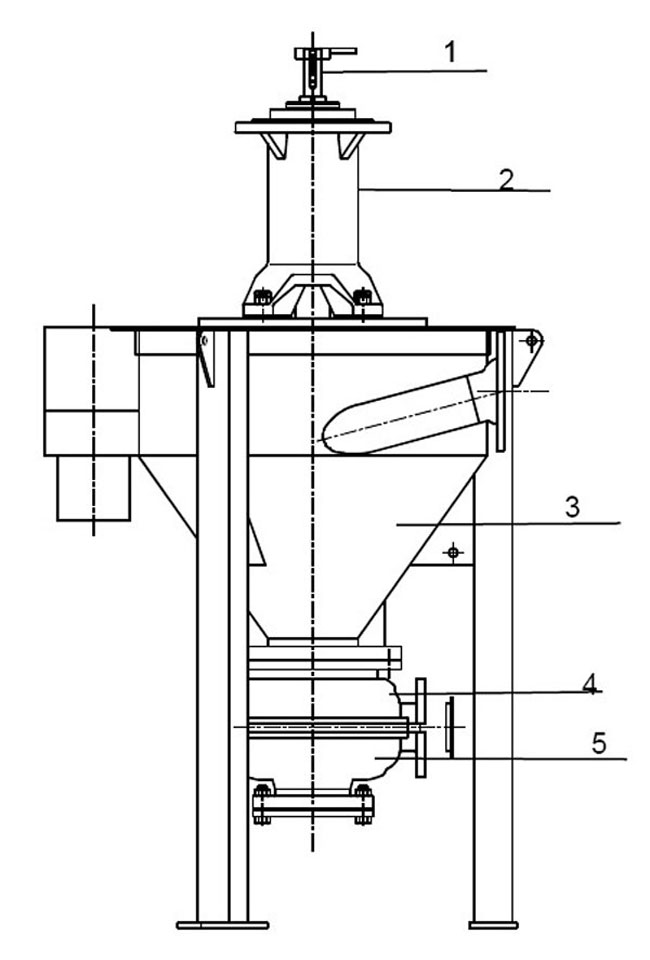

2.Transmission parts of this Submersible Pump are interchangeable with those of SP series.Installed above the Bearing Assembly is a motor mounting base or support frame.Flexible coupling or V-belt is used to connect the motor shaft and the pump shaft.Pump shaft speed is easily adjusted by changing the grooved pulley so as to suit the varying pumping applications.

3.The hopper features a steely structure,complete with the tangential inlet and overflow box.The overflow box can easily send the excessive slurry back to the recycling tank.The tangential inlet allows the frothy slurry to enter into the froth pump while separating the air out of the slurry.

4.The pumping unit is interchangeable with the AH series.According to the kind of medium to be pumped,we can use metal,rubber,or other non-metallic materials to make the wet-end parts of this froth pump.

5.The pump is able to function propertly when there is insufficient suction.

Hydraulic Modeling

1.Air is separated from the slurry in a vortex created by the specially designed impeller and the tangential inlet.

2.Vertical cantilever design eliminates the need for shaft seal or sealing water.

Transmission

Grease lubricated bearing assembly:The double-row tapered roller bearing is attached to the pump shaft while the single-row cylindrical roller bearing connects to the motor shaft.

Typical Applications---

Minerals Flotation Processing

Handle Frothy Slurries

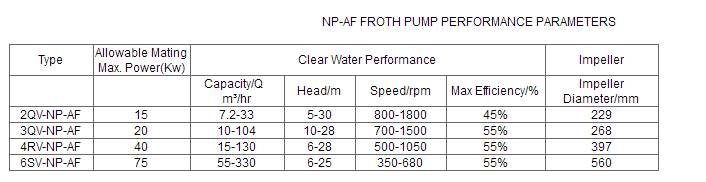

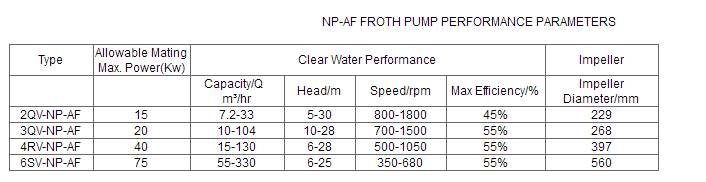

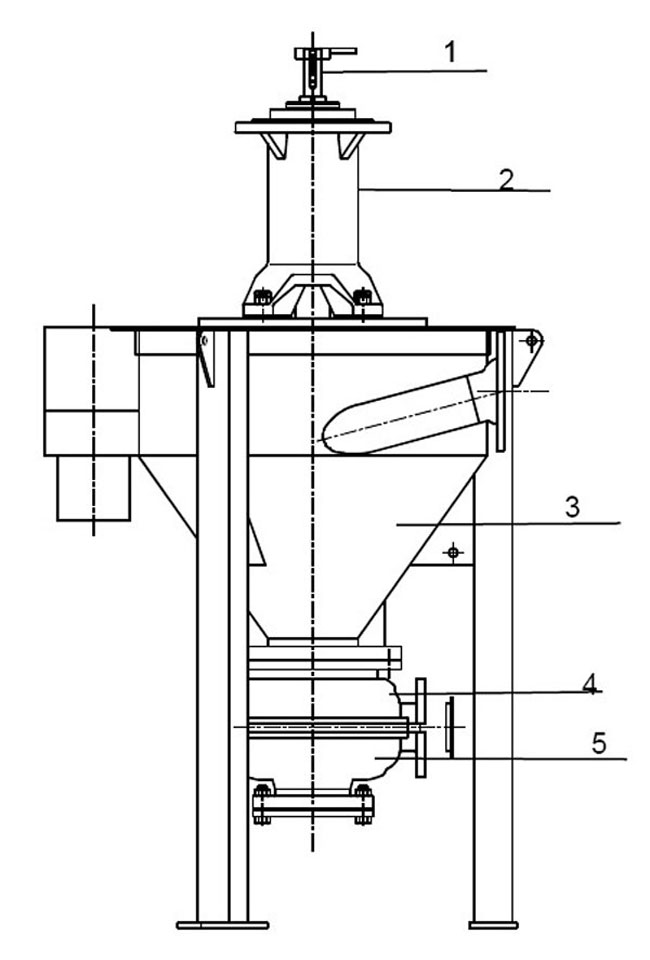

NP-AF Froth Pump Showing Component

Rubber Lined Froth pump/foam pumps/metal lined froth pumps/handling frothy pulp/double casings froth pumps/hopper-tank froth pumps/coal flotation circuits foam pumps.

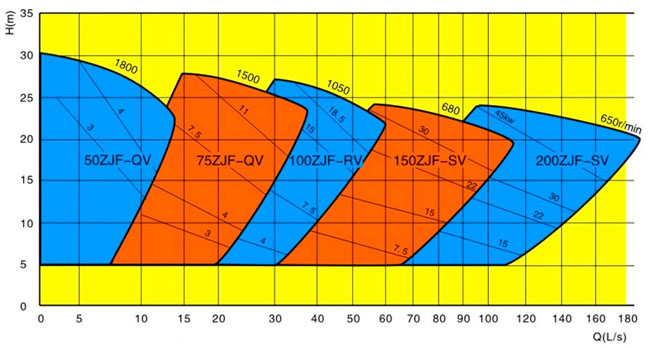

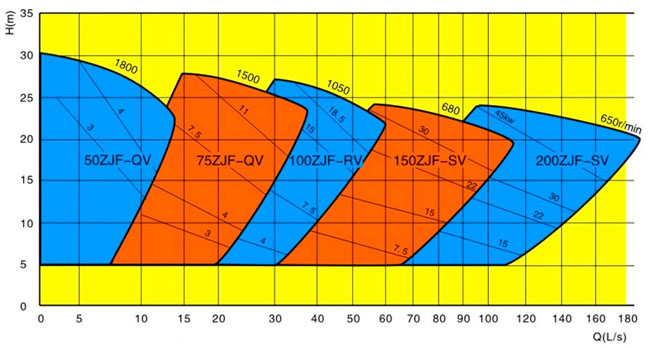

NP-AF FROTH PUMP SELECTION CHART