Y14 Ceramic Coated Shaft Sleeve D075 for Corrosion mining

| Part No. | B075,C075,CAM076,CH076,D075,DAM076,E075,E076,EAM075,EAM076 |

| Material | 3cr13,4Cr13,SS304,SS316,SS316L,Ceramic coated etc. |

| Application | Applied to machinery equipments: cone crusher,textile machinery,mining machinery,engineering machinery,metallurgical machinery,cement machinery,chemical machinery,construction machinery,coal machinery etc. |

| Customized | Can be customized/ do OEM service as your drawing. |

| Main Production Processes | Sand casting,Metal Mold casting and Centrifugal Casting. |

Ceramic coatings Shaft Sleeve

We are a leader in ceramic coatings that provide superior protection from abrasion,corrosion and chemical attack to metal and concrete surfaces.

With Industries facing adverse environmental conditions that attack components and structures,resulting in compromised plant reliability,reduced safety and lost profits,protective coatings is a significant necessity.

Our high performance epoxy coatings and ceramic coatings provide you with long-term protection from abrasion and corrosion,Our abrasion and corrosion control not only simplifies your maintenance procedures,but also reduces your downtime.

Product Overview:

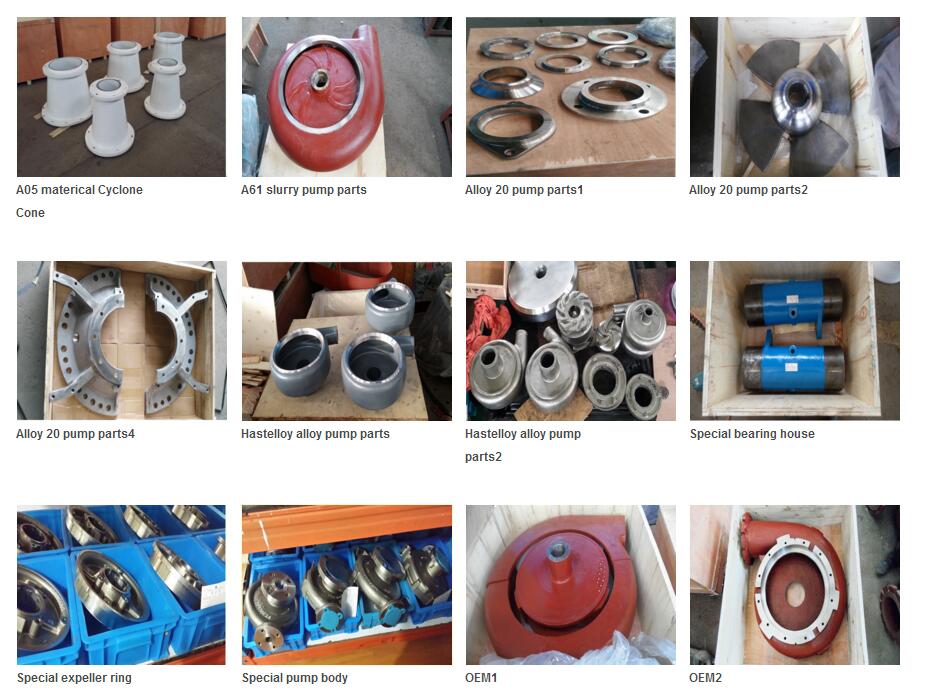

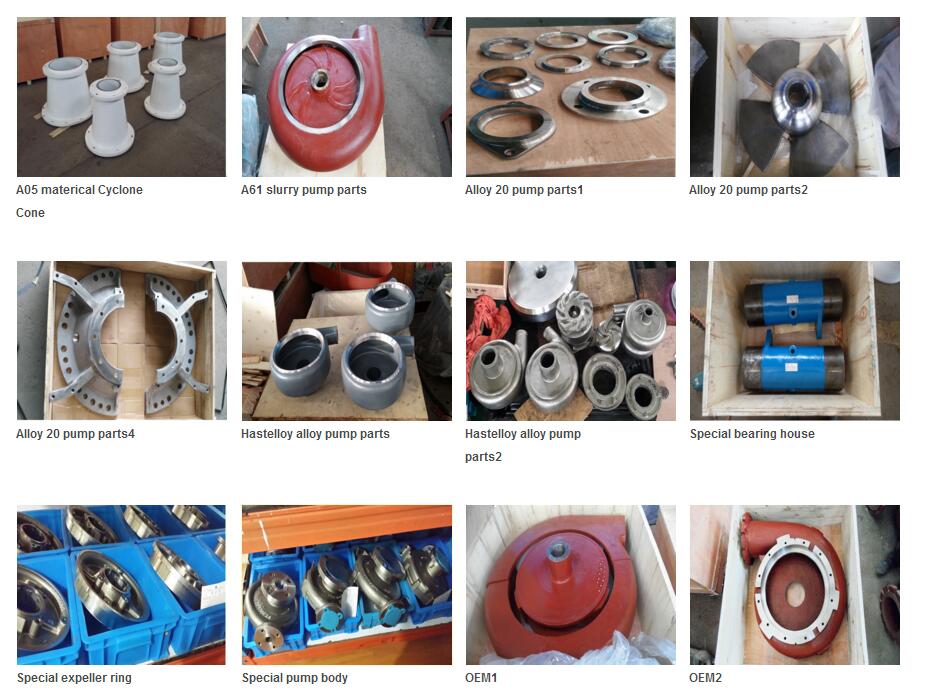

Related Products:

We can develop and produce a range of pumps according to different media situation to meet different duty requirements.There are Rubber Material such as R08 , R12, R26, R33, R38,R55,S03,S12,S31,S21,S42,S51,S52 etc ,Wear Resistant Metal Material such as A05,A07,A12, A33, A49, A51,A61 and etc ,Corrosion Resistant Stainless Steel Material such as 201,304, 316, 316L,C55 Duplex Austenitic-Ferritic,Alloy 20,Hastelloy etc, Ceramic lining parts especially suitable for strong abrasion and corrosion mediums,and they can be interchangeable with standard Slurry Pump Parts Ceramic Coated Stainless Steel such as J04,J05,J21,J24,J25,J26,J27,J31 etc.,Resistant Polyurethane like U01,U38, fully meet customers’ request.

Related OEM Parts

We can undertake various OEM Orders for pumps as well as spare parts customized according to drawings or samples.

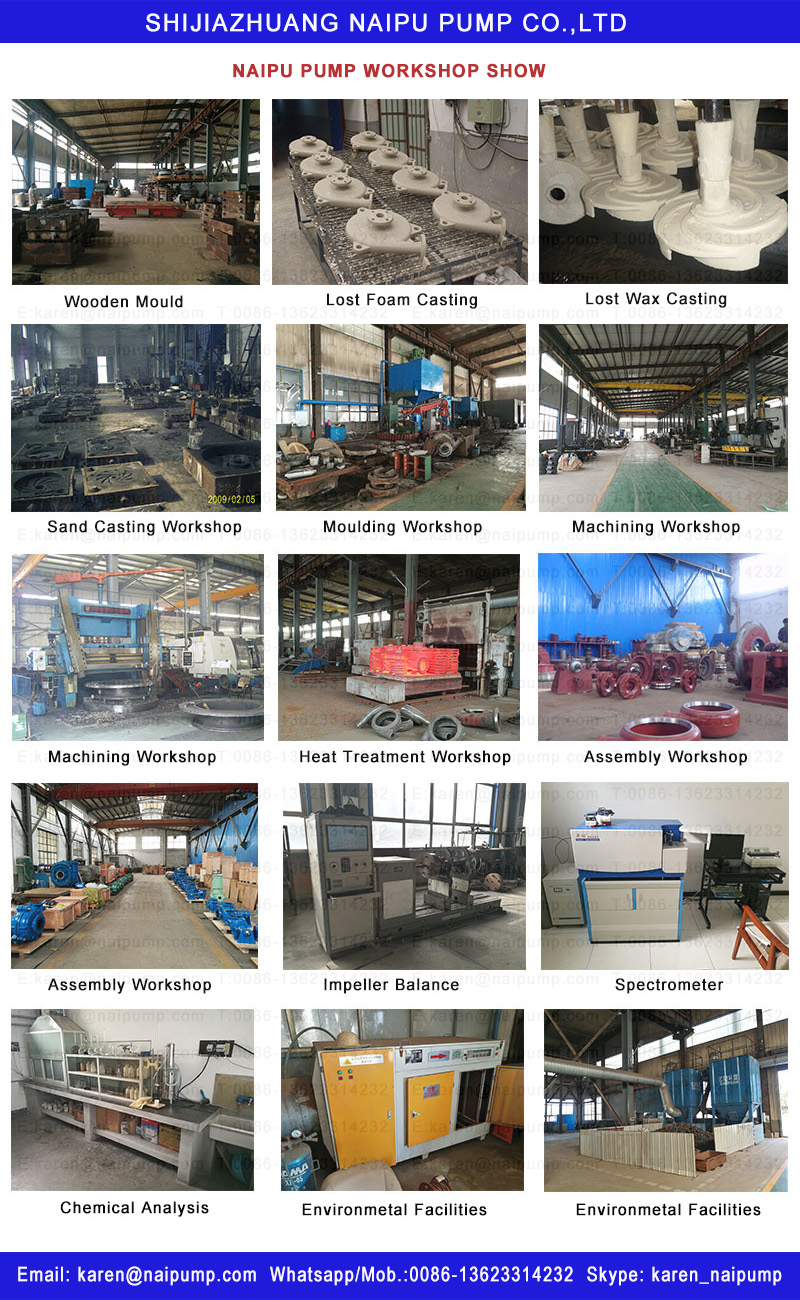

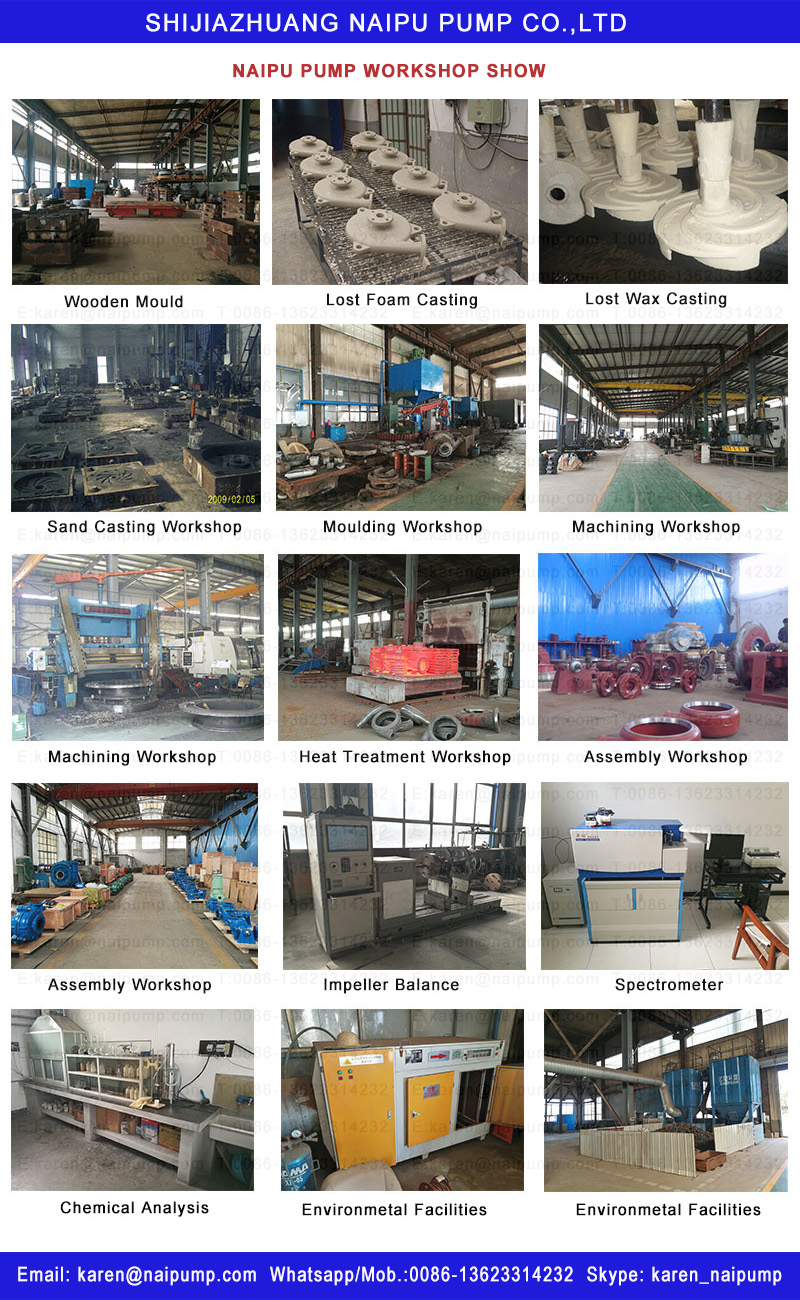

Workshop Photos

We can be in service from Mould ,Casting, Heat treatment ,Machining, Assembly,Testing etc. one dragon service.

We have our Mould Workshop,there are Wooden Mould,Aluminum Mould,Lost Foam Casting Mould,Wax Mould etc.

Naipu own Casting Workshop,mainly Sand Casting and Lost Foam Casting and Precision Casting.

Naipu own Heat treatment Workshop, after out of furnace,the hardness are according to the technical requirement.

Naipu own Machining Workshop,we are professional from rough machining to finish machining.

Naipu own Assembly Workshop, our mechanicians are skilled in assemblying as we had about 30 years experience in this area.

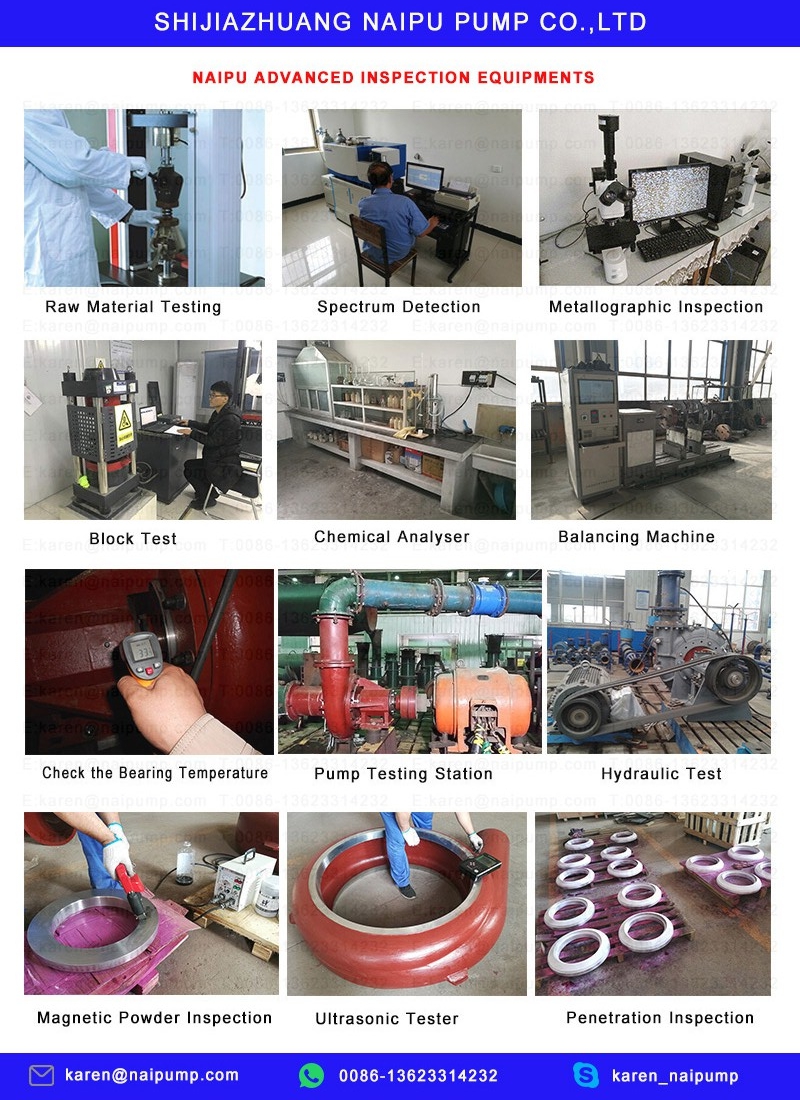

Naipu own Inspection Workshop, Every order every parts we will do the test before delivery.

Welcome to visit our factory!

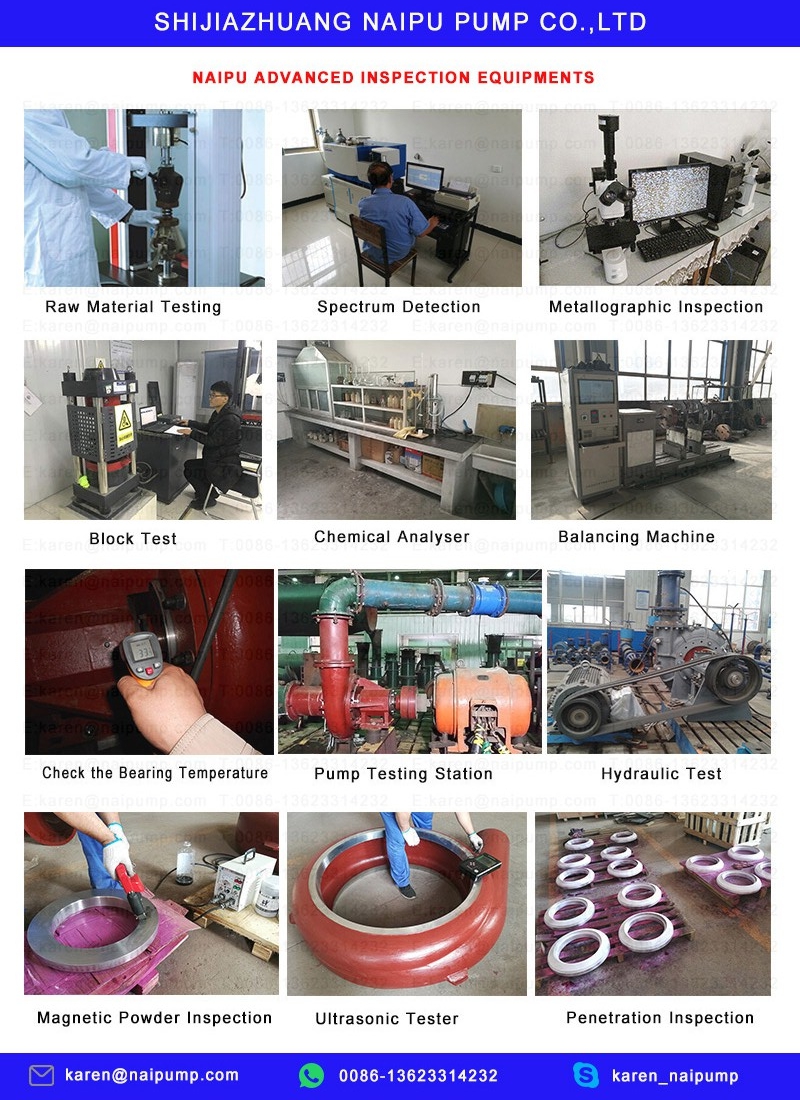

Quality Control:

Contact Details:

Shijiazhuang Naipu Pump Co.,Ltd

Add: No.368 Xinshi North Road,Shijiazhuang Hi-Tech Industry Development Zone,Hebei,China 050091.

Skype:karen_naipump

Contact Person:Karen Tan

If you have any queries,please feel free to contact us.