Sand suction hopper barge high chrome alloy Wet End Parts

Wear resistant cast alloys are used for Slurry Pump liners and impellers where conditions are not suited to rubber, such as with coarse or sharp edged particles, or on duties having high impeller peripheral velocities or high operating temperatures.

Naipu Impeller is one of the most important parts of slurry pump. When impeller is rotating, the slurry pump could meet the requirements of the equipment. However, it is a component, which is worn out very easily. Therefore, for long service life of the impeller, the material plays an important role here.Naipu pump offers the two solutions for this problem. We choose the white iron, high chrome (27%) for the strong abrasive slurries, also with the sharp particles. For the corrosive slurries with blunt particles, we recommend the natural rubber.

Metal parts Material

Metal parts material mainly are A05,A07,A49 as follows.

1. A05 is a wear resistant white iron that offers excellent performance under erosive conditions. The alloy can be effectively used in a wide range of slurry types. The high wear resistance of alloy A05 is provided by the presence of hard carbides within its micro-structure. Alloy A05 is particularly suited to applications where mild corrosion resistance, as well as erosion resistance is required.

2.A07 Marten-sic white iron with moderate erosion resistance.

3.A49 is suitable for low pH corrosion duties, where erosive wear is also a problem. The alloy is particularly suitable for Flue Gas Desulphu-rization(FGD) and other corrosive applications, where the pH is less than 4. The alloy can also be used in other mildly acidic environments. A49 has an erosion resistance similar to that of Ni-Hard 1.

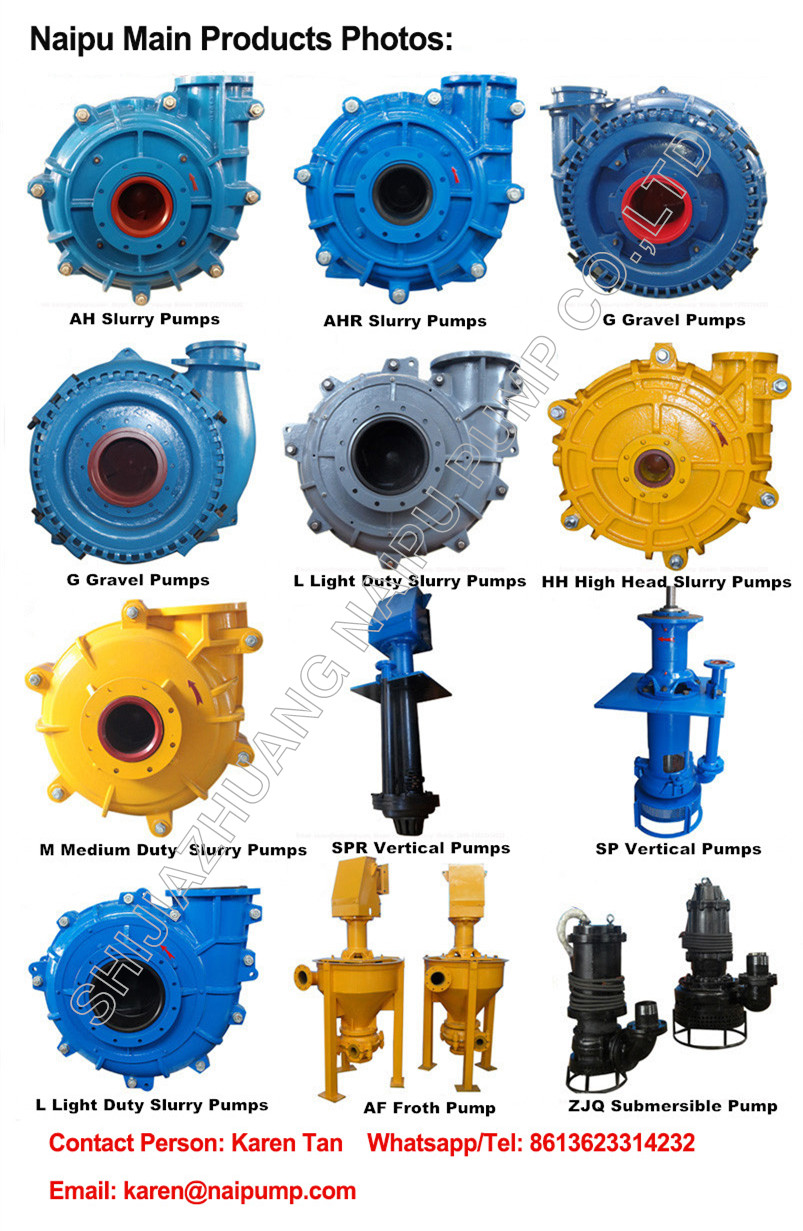

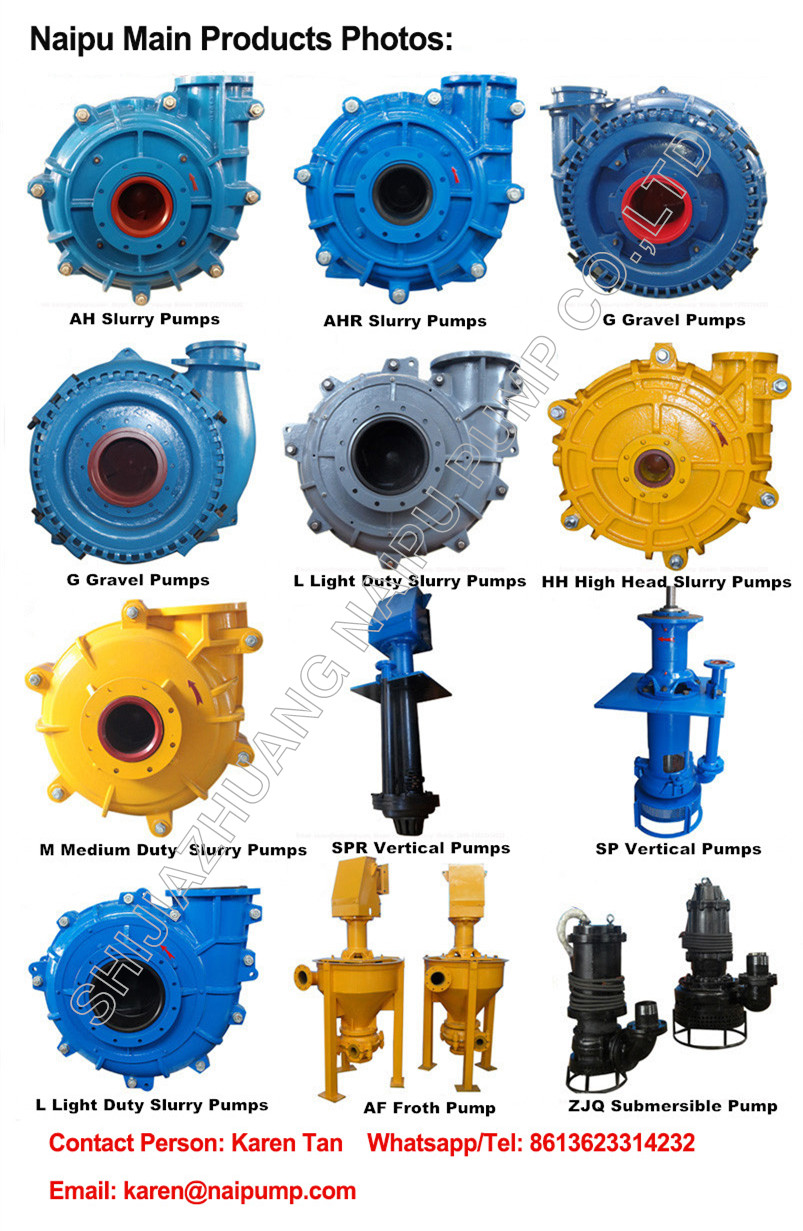

Product Overview:

Our Main Pumps

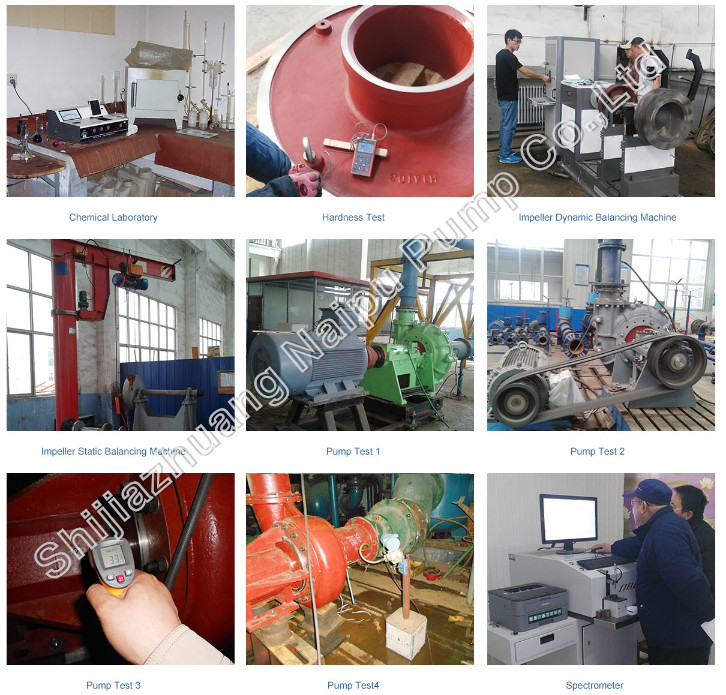

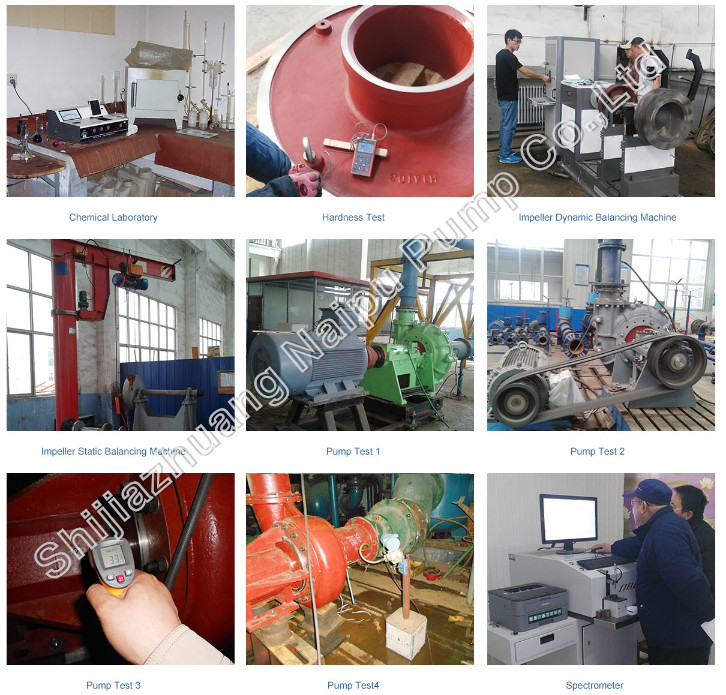

Workshop photos

Quality control

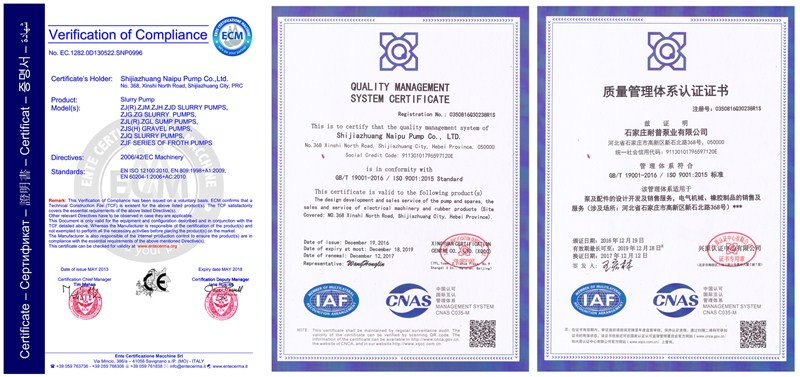

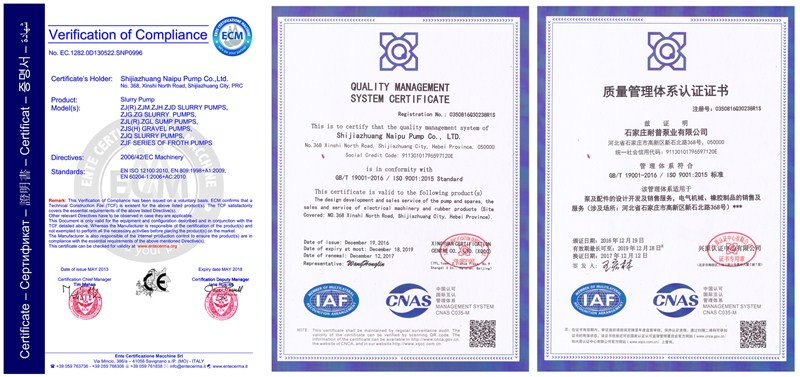

Certificate:

Contact Details:

Shijiazhuang Naipu Pump Co.,Ltd

Add: No.368 Xinshi North Road,Shijiazhuang Hi-Tech Industry Development Zone,Hebei,China 050091.

Skype:karen_naipump

Contact Person:Karen Tan

If you have any queries,please feel free to contact us.